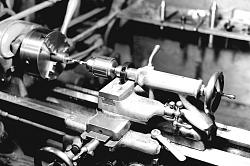

Tailstock power feed. By Haxby_Shed. 27:25 video:

Previously:

38 plans for homemade tailstock mods and accessories

Mini lathe tailstock hand wheel - video

Lathe tailstock - video

Tailstock die holder - video

Tailstock quill lock - video

Revolving tailstock chuck - video

Tailstock spacer plate - video

Lathe tailstock quill lock upgrade - video

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks