A guy from the construction company who has been working in my area installing fiber optic lines ot replace our copper telephone lines asked me to make him a puller so he could drag a 6" pipe through a bore hole. This is what I made for him.

First I laid out a cut pattern for reducing the OD of a piece of scrap 7" casing pipe I had laying around

Next after heating and bending the finger cuts over to start the tapered OD I used half of a 4" pipe union as a forming die and my shop press to close the fingers completing the taper before welding the cuts

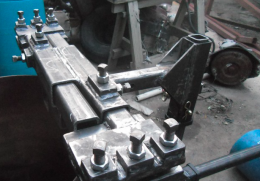

After welding up the cuts I made a pair of Pad eyes and welded them into the reduced opening so a clevis and swivel could be attached for pulling, the pad eyes extend inside the cone a couple inches and are welded from inside as well they align up with the slot in the puller to allow for it being spread open to fit over the pipe

Finally holes were cross drilled to allow a couple bolts to be inserted through the pipe and to clamp the puller to tighten it on the pipe

.

A piece of 6" PVC used to demonstrate how the puller must be slightly spread open demonstrating the snugness of the fit the paint is done with KBS fusion primer and KBS moisture cured topcoat I only painted it so the workers might figure it as a tool to be kept and maybe not just considered of a piece of scrap iron after the job is done

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks