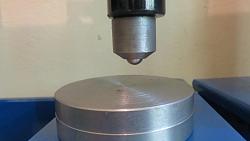

The idea here is to use a regular shop press plus a bearing ball to conduct a Brinell test.

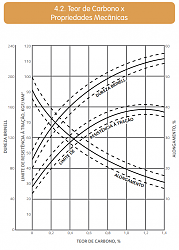

My goal is identify unknown steels and relate brinell hardness with ultimate strenght.

There is a formula witch relate load, ball diameter and indentation to material hardness:

https://me-mechanicalengineering.com...hardness-test/

I Made the "holder" for 10mm (3/8") ball. The holder let only 3mm (1/8") of the ball exposed.

For sure the holder is a must if you doesn't want to brinell test your press ram.

Tested some 1020, 1045, A36, SCH80 and AL 6061 I have at scrap bin.

Problems found:

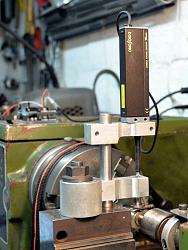

* My readings ended being a bit off expected numbers. Had a tough time taking precise measurements with a paquimeter. I Had read that there is a dedicated microscopes for this....maybe a good photo and convert pixel to mm....this will be my next try.

* Not know the shop press manometer error. Need a way to check it.

Hazards: At 3tons, there much risk of ball bearing exploding? Use safety glasses!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks