Originally Posted by

EclecticNeophyte

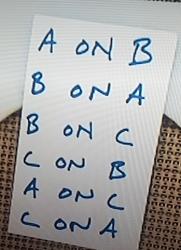

Some time back, I was inspired to make a set of (3) lapping blocks, using 6" diameter cast iron rounds purchased from McMaster-Carr. I first faced them off on the lathe, then cut grooves using my sliding miter saw and a diamond blade. Following that came hours and hours of lapping each of the three blocks (labeled A, B and C) against each other. I didn't reach total optical flatness, but the results were good enough to use for general purposes. I now have three lapping plates that I can re-cut and re-surface whenever needed, just by rubbing them together in the proper sequence.

It wasn't difficult, just a bit tedious with a lot of repetition during the lapping process.

-EN

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks