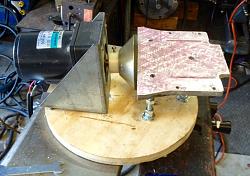

i made a diamond tool sharpener for sharpening carbide metal scraper blades and biax carbide blades.

it turns at approximately 280 rpm.

the wheel is 75% concentration diamond 600 grit, 3" diameter.

i use a few shots of windex to cool the carbide during sharpening operations.

the platen is flat and level, the motor is tilted 3* and is adjustable.

thanks for reading

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks