Well talk about me having a 'Duhh' moment. Mark.

I get it now.

Thanks for the quick response, too

Regards

Doc

Last edited by astroracer; Mar 24, 2015 at 10:24 AM.

Haven't been out in the shop for a week. Had stomach flu for 4 days and am just getting back on my feet. Got out in the shop Friday afternoon and made some adjustments to the FrankenMill. The spindle was out of square to the table in both X and Y directions so I spent a couple of hours trueing that up. Also removed 95% of the backlash in the X lead screw and cleaned and lubed all of the ways. Took a couple of hours and, after being sick for a week I was pretty well done for the day. Anyway, the mill is working very well and getting the spindle squared up was a good thing.

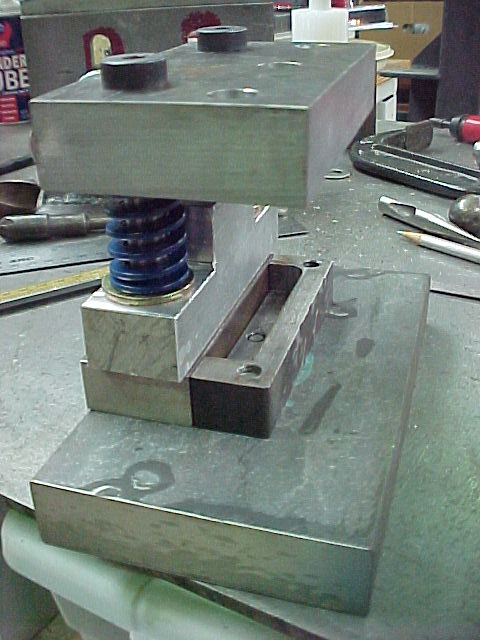

This is the stripper block to help hold the work in place while punching and also to help strip it off the punch as it withdraws. This was a rough machining operation before finishing to size. I did this work last week before getting sick which made me realize how bad the spindle alignment was. You can see the lines in the work caused by the out of square spindle. I had some work to do to get it right. They were very prominent.

Just looking at the block you can see the corners are not square...

After truing up the spindle I got a much smoother finish with no edges to catch with your finger nail. I am pretty happy with this setup.i was using a 1" dia. end mill so, if there was anything amiss it would be evident.

Continued next post...

Last edited by astroracer; Mar 30, 2015 at 07:35 AM.

After drilling and tapping for some shoulder bolts I mocked up the bolts and die springs that will be the working features of the stripper plate.

Sitting in approximate orientation to the punch die. The stripper plate will be bolted to a 1" thick upper punch plate that carries the louver punch. I have to order that steel tomorrow.

Mark

Got some more work done on the die this past weekend. I made the upper punch plate and have the punch block and the punch itself roughed out.

Here are some pics of the upper plate with the stripper plate installed.

Compressing the die springs in the vise. Everything works nice and smooth.

Sitting in place on the lower die.

Last edited by astroracer; Apr 6, 2015 at 05:04 AM.

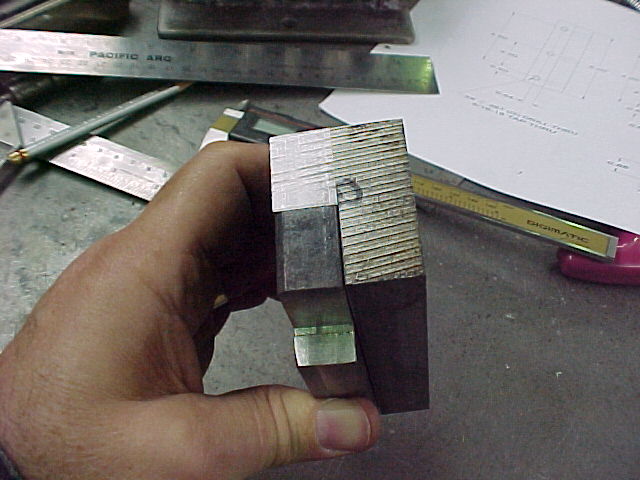

Here are the punch and punch block. I still have to drill the mounting holes but the hard work is done. Shaping the punch will be the last thing I do. I should be able to have this finished up this week.

The punch is made from a piece of 5/8" plate and the punch block was cut from a piece of 1 3/8 x 4". I will get everything bolted up and trued before I shape the punch.

Last edited by astroracer; Apr 6, 2015 at 05:00 AM.

Just a note about cutting and my using my Taiwanese 4 x 6 bandsaw. I have had this saw since 1978 and have spent a lot of time getting it to run and cut consistantly. When I cut out the punch block I mounted it vertically in the saw. This is a five inch tall piece when clamped in place.

The saw took about 10 minutes to chew it's way through this block.

When it was done, the difference in width from the top to the bottom of the cut was about .001.

Top of the cut.

Bottom of the cut.

I think that's pretty good for a cheap azz saw.

bobs409 (Sep 2, 2017)

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks