This is my bending brake.

I made it from 4mm thick 40 x 40mm L-profile

6 and 12mm steel bars.

And 3, 4 and 6 mm thick flat bars.

This short video shows my space saving idea in it:

I wanted to get brake that could bend 2-3mm thick steel. Also i wanted to be able to do some bends with bigger radius, without noticeable marks. That's why i made bending radius adjustable.

This video shows the actual making the frame:

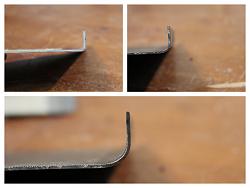

You can see the main idea of the structure and the radius adjustment from these pictures.

I bought hinges, screws and nuts from my local hw-store. Those costed 5 euros.

All other material is from the recycling center and costed 30 euros.

Used tig for welding, but it could be done with mma, mig/mag too, of course.

Closer look for the "corners" little groove allows to make brackets and stuff like that.

I like to use tig, it doesn't make splatters. Build was very simple process, all parts are cut straight.

I used chop saw and angle grinder for cutting. But that's optional.

Drill press and hand drill.

M6 threading tap. M12 threaded rod. M6 nuts and bolts.

2 pieces of tight springs. Washers.

This video shows the radius adjustment:

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks