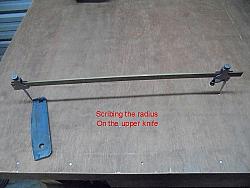

I’ve had the idea of making a hand shear for a while, it’s not something I will use on a regular basis in the machine shop but it will indeed come in handy from time to time, instead of sawing everything now I can shear allot of it, it will cut straight lines and radiuses on mild steel up to 1/8” in thickness, it will cut 6” in width but could be made to cut wider, 6” will work just fine for me.

The upper and lower frames were constructed from 3/4” A-36 steel plate, the blades were fabricated from A-2 tool steel hardened tempered and ground, the lever and linkages were made from 4140 steel hardened and tempered, the handle was fabricated from 3/4” schedule 40 pipe, all assembly bolts are socket head cap screws, the shear is mounted onto a heavy wooden work bench for rigidity.

Mild steel would work for the construction of everything except the blades, using mild steel for the linkages and levers would soon wear out due to the force it takes to shear metal, using a heat treated alloy steel for these parts greatly lengthens the life of the tool, all pivot points use 1/2“modified shoulder bolts, shoulder bolts are heat treated and ground round and fit nicely into the reamed holes, there are a variety of metals the blades can be made from such as A-2, D-2, H-13, S-7, HSS and a few others.

The shear was designed to last for many years, it was designed with close fits and tight tolerances, the blades can be resharpened many times over.

Below you will find some photos of the construction and a few examples of the shear being used, hope this will be helpful.

As always thanks for looking

And Happy Machining

Doug

Machining the plates

Tapping all the holes

Making the blades

Modifying the shoulder bolts using the carbide threading tool holder and extended point live center I previously made

All parts made and ready to assemble

Testing the shear

Example of cuts

Straight shearing

End view

Shearing

Overall view

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks