Hi,

I put together the couple of last tools I posted here in an application video showing how I have reground a badly manufactured ER32 collet chuck :

I tried to explain the rationale in the video subtitles, but the key points are :

- It is a CM2 chuck, and my metal lathe spindle is CM3. So I decided to do it on my wood lathe, which has a really high quality spindle.

Additional, I didn't want to use a CM3/CM2 adapter to put it in the metal lathe, it would introduce more run-out.

Other reason, I try to avoid metal grinding as far as I can on my metal lathe. The wood lathe bed is less sensitive to the grit, a shot of compressed air and everything is clean.

- I used an ER collet to setup precisely my 8° angle. To hold it in the spindle I chucked a ground 8mm bar in a good quality 8mm pull-back collet.

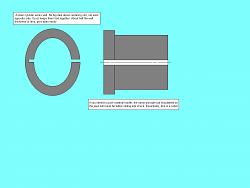

- I needed a stone larger than the ER11 chuck of the HS spindle. The only one I had was this ball shaped white grinding bit. But it was not well centered so I started by trueing it up in the spindle, using a diamond tool

- Obviously, with my setup, I miss the transversal slide, to take passes. As I show on the video, I have clamped on the bed two parallel cawls to keep the tool rest base perpendicular to the axis and thus avoiding to loose my angle setup. To take a pass, I just loosen the crank, and lightly tap with the plane hammer. It is low tech, but works pretty well.

Finally, I am pretty happy with the result and again, this HS spindle is really the killer tool ;-)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks