Hi All

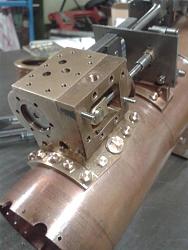

This is a short video on setting up two individual tool holders on the Dickinson tool post to face and chamfer in one operation on the lathe.

Saves a tool change or reloading each component to chamfer after facing.

I hope you find it of interest and thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks