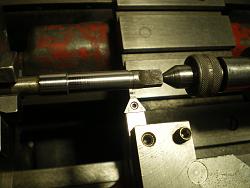

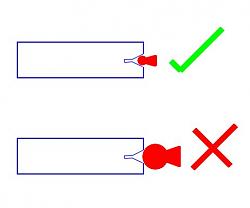

Like most I am reluctant to disturb my tailstock from its dead centre setting. Rather than make a new device I decided that my small boring head would do the same job, all I needed was to make a new No 2 Mt shank to replace the No 3 which is usually fitted. Next was a decent hard centre to fit it and I turned one from an old end mill with my CBN tool, the swarf this produces is as abrasive as grinding dust (tiny shards of flying HSS chips) so lathe and eye protection is needed. So far this has worked very well and will suffice until I finally get around to making a taper turning attachment.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks