Hi,

I have always been attracted by the lantern chucks I have seen posted here at HMT, and have planned to make one, one day ...

But as I was recently shopping at the local hardware store, suddenly the light came. I saw a kind of big hose brass fitting like this one :

I thought that I could do something quick with that, just adding a brass cap nut and a core screw in order to hold any hex screw driver tip to lock the screw against the cap.

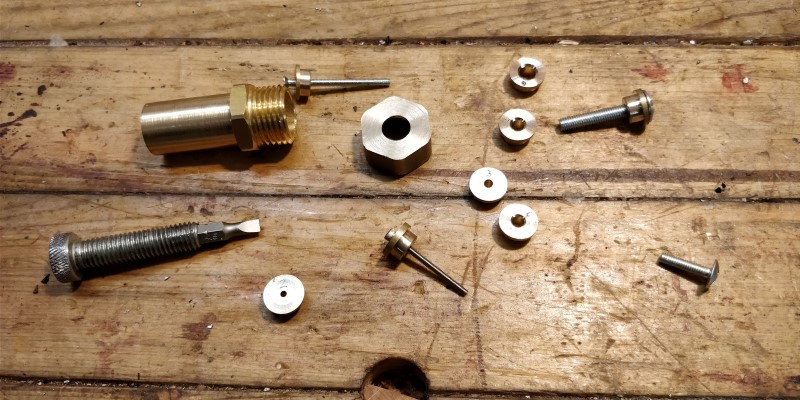

Here are the main parts :

- on the left, I machined and tapped a sleeve that will be "loctited" inside the brass.

- the M10 screw will have to get an hex female hole at the end to receive an hex bit like the one above on the picture.

- The brass body has its main part turned down to make the shaft

- The cap was surfaced true, on both sides, and a 8 mm hole is center drilled.

And here the collection of bushings in order to fit any screw diameter : 2, 2.5, 3, 3.5, 4, 4.5, 5, 6

they are lightly counter sunk in order to fit either flat or counter sunk headed screws

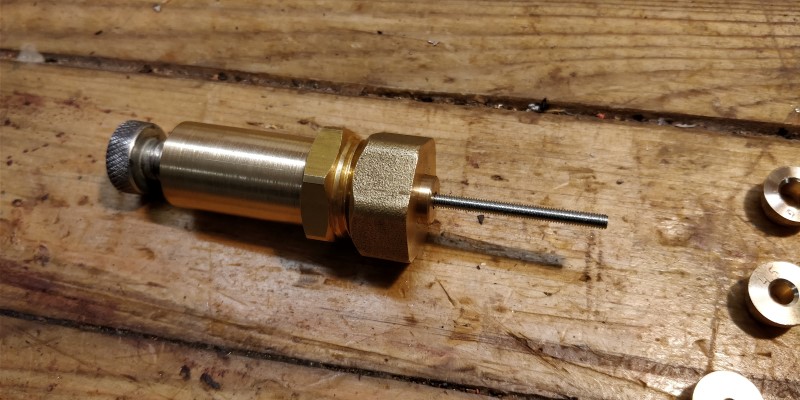

The screw head has been (badly) knurled and the hex tip has been made.

That's actually the most difficult part of the job. I drilled a hole smaller that the hex diagonal and then pressed an hex tip in it.

I removed it and tried to file the inside with small files and a dremel in order to get a slip fit.

I had to use a dye to readjust the somewhat expended threads as well.

And here is the assembly and mounted on the lathe.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks