re: Bridgeports, drill presses, anything with a stop; via accessible rod and nut.

Often, I use R8 QC tooling, especially on holes. Steps from center drill to ream or tap involve tools and holders of varied operating length. If part(s) have sufficient repeat operations, I employ this intermediate stop. One instance; stopping center drill or countersink depths, insert collar to control those, perhaps when drilling or others go through material. Also works for drill & ream of blind holes; tools are chucked at a length so drill depth exceeds reamer and collar differentiates them.

Harder to describe than trying one out.

Naturally works without QC too. Placed above the quill stop knob, you might mill a depth and remove the collar, to clear work and move to next area. Sometimes beats raising and lowering the knee...and accurate enough.

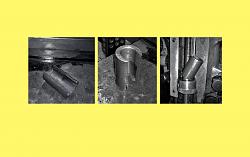

Easy to make, there isn't a particular length, about 1 1/2 seems to accommodate most times. Easy to make. Face both ends of heavy tube or bar stock, drill a bit over rod size. Counterbore a depth, if like a Bridgeport, a protrusion extends from adjustment nut, so it doesn't interfere [deeper]. Slot the collar for rod clearance.

Done!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks