Hi folks

Currently my mill is on a shelf with a chest underneath for added support. This arrangement was only temporary until I coild find something more suitable. As it happened, a combination of discarding from work provided all I needed to make a decent stand for it.

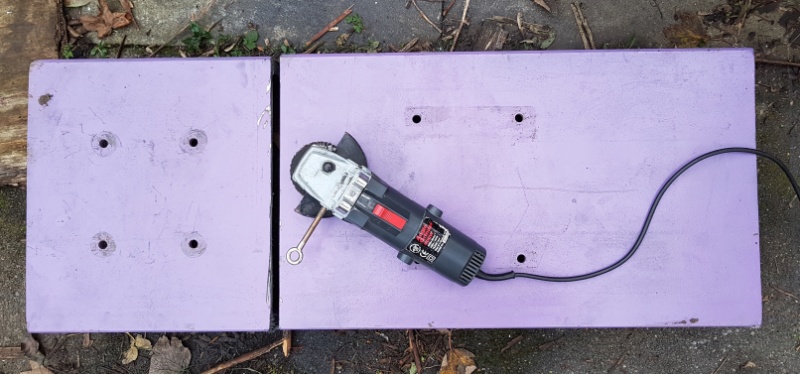

Just outside the goods in entrance was a 5kw motor and 1.5kw motor bolted to a very substantial U profile steel base which measured and cut to length using my angle grinder:

The rest of what was needed came from round the back of R&D in the form of a pair of pre essembled 40mm extruded T slot aluminium profile, I just cut a couple lengths to make it the correct width and used the fixture I found still attached:

After that I took some measurements, marked, drilled and tapped a set of holes to bolt it to the frame, making sure it sits high enough so the sloping sides don't interfere with the x axis movement or handwheel:

It was getting dark by the time I managed to get the last bolt in as I'd miscalculated hole distances but got there in the end:

I still need to cut a large hole in it for the main shaft so I can lower the head but at least I haven't got to cut through as much metal as there is on the sides...

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks