Recently I made a post outlining a shock dynamometer that I'd made. http://www.homemadetools.net/forum/s...amometer-56478

In that post I mentioned in passing, the temperature sensors that I used on the shocks being tested. There seems to be some interest in these sensors in their own right, hence this post which will go into greater detail. I have made several of these sensors and use them in various applications such as the shock dyno mentioned but also on a flow bench as another example. The flow bench will be the subject of another post in the future.

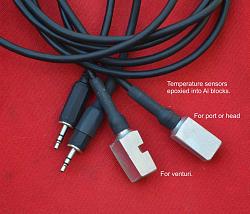

Here are examples of the finished sensors.

The base sensors are of the semi-conductor variety and in many applications they are too delicate without some form of protection. To that end I make an aluminium housing to suit the application and pot the sensor using epoxy. I use either an LM34 (deg.F) or an LM35 (deg. C) chip which are simple 3 wire analog devices. There is an earth or common wire, a power supply wire and the 3rd is the DC signal output.

The sensor shown with my housing prior to potting in epoxy.

On the left the sensor and soldered cable encased in wet epoxy, next we see the sensor potted in the housing.

Some heat shrink tubing over the cable entrance is used to seal it and provide support for the cable. This finishes the assembly and makes it suitable for harsh environments.

Here is an example showing a sensor fitted to a venturi used for flow measurement.

I'll go into more detail of how I deal with the output signals when I make the post on the flow bench.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks