Hi All

i don’t normally make a tool if I haven’t got a job for it but I am fascinated by rotary broaching. Anyway cutting a long story short I have made one and am very pleased with the results so thought I would share with you the build. I bought the bearings, tab washer, locking nut and two arbours (R8 and a 3MT).

Before I get on to the build I will try and explain how rotary broaching works and what it is used for.

Rotary broaching is a form cutting process and both internally and externally forms can be produced using this technique. (I am interested in internal forms) Examples of forms are squares, hexagons and splines which can all be produced.

The broaching tool body has the internal shaft supported on bearings angled at 1 degree angle which obviously allows the tool to run off centre (a bit like a drill that hasn’t been correctly placed in a chuck and then runs out). As the cutting tool is in a housing supported on bearings the tool, when it comes in to contact with the work piece stops rotating with the spindle but moves in a oscillating motion and this action allows the corner of the tool to cut the form of the cutter in a pre-drilled hole.

A tool needs to be made with the desired shape and size to be cut. When grinding the cutting tool flanked clearance is needed at approximately 2 degrees for clearance and the bottom of the tool relieved to give a sharp cutting edge.

One drawback is the cutting tool needs to be positioned at a known distance from the centre of the broaching body centre line to allow the cutter to produce the correct size.

I hope the photos will clarify my explanation on how the tool works.

Material and purchased items

centring work piece

Main body set at 1 degree

machining location tongue

Tool shaft

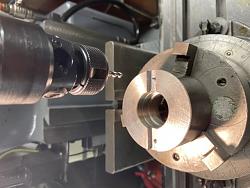

Truing the outer body in the lathe so this runs concentric to the main spindle. The internal bearings and tool shaft maintain the 1degree angle to allow too to oscillate.

machining shanks for c-spanner

Shaft screw cut for purchased bearing locking nut.

Internal shaft thread and machined to accept locking tab washer.

The thin bee-blocks make it easy to clock to find the centre. Link to vee-blocks Story of the little discarded beat up Vee block

grease hole for bearings sunken in to body to avoid nipple protruding outer body.

completed parts ready for assembly

Completed body

Cutting tools from old slot drills

3/16” hexagon in steel

Aluminium

Thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks