This is my first post ever.

RIFLING MACHINE

10 years ago I made rifling machine of very simple design and later on when I had

internet access, found that some more clever people did it using much better design

and they did it in 1853. Just google '1853 rifling machine' and you will find it.

Must say that I am seaman and at that time I didnít have internet access on board.

When ashore I didnít have time for internet cafť. I was younger and I was spending

most of my free time in bars, pubs, night clubs and discoteques.

Life is much easier nowadays. Have internet on board and I no longer make bars.

At that time I was aboard brand new cargo vessel with brand new professional

grade lathe and milling machine. Once when I was in Hong Kong, I found Canton

Road, the street with so many shops for all kind of tools, bearings, gears, v-belts, etc.

You name it, they have it there. (picture 01) The street next to Canton Road is

Reclamation street and there I found aluminum shop where they cut aluminum to

required size and they do it immediately for additional small fee.

As I already had idea what to do, I decided to buy parts in order to build rifling

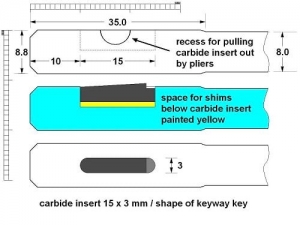

machine, so I spent approx. 400 US Dollars for 6 bearing housings with ball bearings,

8 pieces linear bearings dia 20mm, 3 meters of 20mm shaft, 50cm geared rack

2 gears (one for 9mm Luger and another for .22 LR calibers), couple of aluminum

plates and whole bunch of bolts and nuts. Gear sizes were determined in the shop by

turning the gear on the rack for one complete turn and measuring distance.

Design is very simple. Changing direction from longitudinal to rotational by

means of gear and pinion. That came for free as I took it from vessel's spares.

These were gears and pinions of Nitto Kohki angle grinders. Extremely accurate and

also extremely expensive, but as I said that came for free. Took me couple of months

to complete the job. In the meantime stopped with machining aboard vessels, as at

home I have 11 x 26 cutmaster lathe and 6 x 26 mini knee mill (harbour freight 40939).

Both made in China but not so bad. Canít afford any good quality machines (read heavy),

as I have more than one hundred stairs from the street to my house. From 10 attached

pictures it can be seen what machine looks like and pictures 09 and 10 show recent

condition of rifling machine. These last 2 pictures were taken when I was rearranging

my workshop. Machine is not in use anymore and I am planning to use sliding parts

(linear bearings and shafts) to convert it to cut off saw.

Hope that this article will help someone to build his own rifling machine.

LMMasterMariner

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks