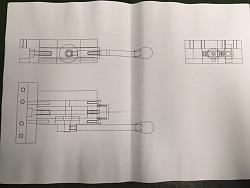

Retractable internal screw cutting tool

Hi All

Over the last couple of weeks, I have been designing a retractable internal screw cutting tool.

The reason for this post is to judge what interest there would be in purchasing a set of drawings once I have manufactured a prototype to prove the concept. If all goes to plan would like to make the drawing available via the Homemadetools.net. tool plans area. I will be making the prototype over the next few weeks (time permitting) and will keep you update on my progress.

I have designed the tool to be used in conjunction with my Colchester Student 1800 Lathe. But I am sure the drawings could be scaled up or down to suit the individualís needs. The drawings have been constructed on Auto Cad and I am going to create a diary on the manufacture to support the build with photos and a bill of materials.

The plan, if there is any interest, is to sell the drawing for around $10.

I have posted a G.A. of the concept as a taster, the finished drawings will be fully dimensiond and a boarder and title block will be set.

I would appreciate any feedback or comments about selling drawings/plans/designs etc.

Thank you again for taking the time to view.

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks