Good morning gents,

I got an old but refurbished TIG welder last summer, but after giving her some inspection I found she needs some of her capacitors replaced with new ones. The seller/dealer said she got a lot of cleaning inside, seems it's true, but yet some hard-working parts are showing some signs of deterioration. It was fortunate to me that I was able to bumped into an engineer who has been working at a local welding school(may be it is operated local government officially). What he said was all very accurate in detail about the electrical functions of this machine, and the way he told was generous and gentle. So gradually some doubtfulness in my mind faded off, and got inclined to put trusts on his words.

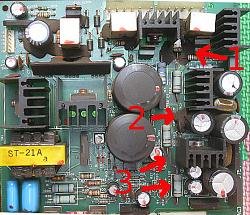

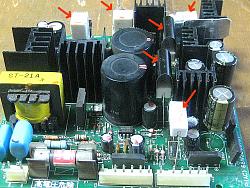

He said in the early models of this set-up, he encountered several cases of issues on a set of capacitors on the very limited area of the circuit board, the power supply board.

Capacitors_MB_board_05_s.JPG

Area with red marking in above, and the said capacitors are the larger round stuffs with red arrows. He said these capacitors tend to get a lot of electrical stress when we use the welder in excessive duration of time with higher amperage, while others around them are not like that. Actually he showed me some data he has got when he has made examination on other capacitors, that tells the other stuffs have been working all right on this model.

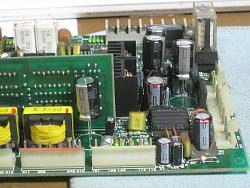

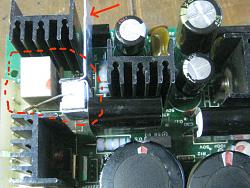

Capacitors_MB_board_00.JPG

When I saw the top surface where you see the 'Y' marking above, these marking show no sign of distortion. (Incidentally in some bad cases this Y mark shows some rise upward, tells this part gets pressure inside. )

So I told him this fact, but he replied that still there is some possibility of deterioration in the capacitor which causes oxidation to the brazing area of the board.

So this words of his led me to the next attempt to remove these capacitors as below,

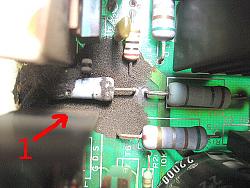

Capacitors_MB_board_03_s.JPG

and see how the colors of the 'land'.(they call the small holes with copper plating on any circuit board 'lands/land')

These lands, especially where I marked with red arrows has got some dirt around them.

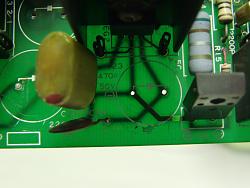

Capacitors_MB_board_01_2.JPG

In the worst case, if we keep these untouched, these oxidation go farther deeper to the copper plating of the board, and finally invite disconnection to the part. Yet an examiner/user may not be able to find out where to be repaired, since the issue is undermined at the foot of the capacitors which looks pretty good at glance!

Capacitors_MB_board_06_s.JPG

Could you guys tell what are the new capacitors I replaced, they are all a tad smaller than the old. Small but has better durability to the load, the old bears 85 degrees Celsius, new 105 degrees.

to be continued...

Chy

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks