Some of the manufacturers, sellers or users (on different sites) swear by Vactra ISO 68 for their lathe's bed & way use.

An excellent product, sure - but neither easily nor cheaply obtainable in a quart or litre bottle for an average Johan.

-Litre/ Quart bottles of this at your gas station? Forget it.

Companies buy them by the barrels, drums or 25 L canisters.

So how did I do it- particularly as I don't have any domesticized farmers or elevator service guys

in my small and diminishing social network?

Well, brew my own at home, of course. -Yup - You read the title, and now you want the goodies?

First some line of thought and facts!

Given that I've found an entire drum of clean, unused (but 40 years old) Shell Tellus hydraulic oil at work,

for most of my lube needs there,I thought along "putting some sort of thickening, adhesive additive into it"

to raise the viscosity from the original's ISO 32 to abt 68-ish,

but also to make it a lot less runny and much more "clingy" oil...

-So what additive would that be, then?

(Drum roll inserted here): Saw Chain Oil of course! Easily and cheaply optained just about everywhere -

thick, gooey and clinging to a saw chain whizzing thru logs and mothers-in-law fast enuff to get a speeding ticket.

I guess not many of you guys know the viscosity of that either? So I checked: Around ISO 125-ish, give or take 5.

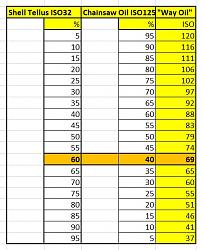

So: Mixing the two parts together - what ratio should I have for reaching ISO 68? -Just wait - we'll come to that, eventually.

The vegans/ vegetarians/ sensitives or Algerians might want to flame me for this, but I don't particularly need any more biodegradable stuff (apart from myself) disintegrating, smelling or gumming up on or near my lathe: so I went for the cheap, crude fossil variant by relapsing: totally tripping out on a Spreadsheet OD:

Mystery solved (for my intended purpose and ingredients) - take 6 parts of Tellus and add 4 parts Cheap Saw Chain oil!

Tip if you're Really Cheap and Sneaky: Mix only 3 parts Tellus to 2 parts Chain oil, instead!

So - if you have vast amounts of thin oil and want to thicken that - take a few minutes and set up a spreadsheet like the one above and "get cooking":

There you had it - no fancy stuff - this time either! But then again - YMMV!

Thoughts, comments, corrections welcome.

Johan/ DIYSwede. Motto:"-Quick, dirty, cheap and operational!"

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote I would give extra thanks for the funny text if it would be possible.

I would give extra thanks for the funny text if it would be possible.

Bookmarks