Hi All

After receiving the vee-belts in the post I soon realised the eccentric plummer block would not offer enough adjustment to tension both belts. So a re-think was needed and a solution to this problem.

I decided to manufacture a hinge plate the plummer block could be bolted too and operated via a single screw to tension the belts in conjunction with the motor adjustment and the eccentric plummer block. The eccentric was also difficult to adjust so a handle was made to rotate the shaft.

Link to previous post.

Powering homemade sheet metal tooling (Table and motor arrangement)

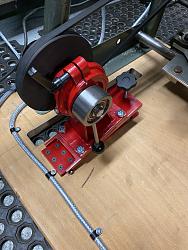

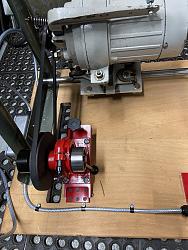

The photos below show the solution.

Painted components ready for assembly

Eccentric casting housing machined to accept operating lever.

handle drilled and tapped at angle to give clearance on plummer block body. This tapped hole also locks the handle to casting.

The base plate was made from 6mm aluminium and the hinge was made from another piece of 6mm plate bolted together and drilled on joint center line to accept 8mm pin.

Screw showing additional adjustment

Ready for final assembly

Fully assembled

Bolted to underside of table top

After setting up, the belts can be tensioned relatively easy and a new length belt for the bead roller is need as the one i purchased is to short but the slip rolls worked out a treat and have had them rotating via the drive.

New belt on order for bead roller.

Thank you for viewing

Thw Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks