I am seeking advice about some drills I have got, which have not been used since they were re - ground, although their shanks show heavy scarring.

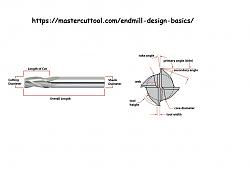

The larger on the left seems to be a slot cutter

The smaller looks as though it is for drilling

But if so, what material?

I should like to experiment with these on a variety of materials (and, yes, I do know that material must be secured firmly)

I do not think that I will use the good keyless chuck on my drill, but will use a spare, but do you think I might damage the spindle if I am too rash?

I have bought a compound table and vice so can move very cautiously and will select the lowest speed at first. I shall start with acrylic, then aluminium and then possibly brass or even steel.

What do you think? As ever, very grateful for your advice.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks