Hi All

I made this radius attachment to assist in the manufacture of dies for the ever ongoing bead roller project I started. I had a shopping list that I wanted the tool to meet.

1; a radius attachment that would be able to produce both internal and external radius

2; must fit a standard tool-post holder so the top slide could stay in position.

3; Tool setting the required radius.

4; Adjustable stops to control the angle the tool could be rotated.

I had previously made a radius attachment from a cheap Chinese boring head led on its side which was compact but difficult to set and I felt was limited in it uses. So a new one was needed. I did use some of the parts from this tool and modified to suit the new, hopefully improved radius attachment.

I had an idea in my head (very dangerous I hear you all say). So with the blue prints in my head off to may scrap box to see if I could find some material to suit the design. Luckily I did have all the materials to hand and set off making the tool which was completed in three days.

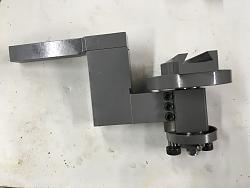

The photos below show the finished components and the assembly.

All components finished and painted ready for assembly.

Main shaft and base plate

Main shaft fitted to two bearings in modified body from old tool

Main body and shaft held in place with adjustable rotation stops assembly. The stops are shoulder bolts and move in a slot and clamped hand tight to desired position. There is a stop bar attached to the main shaft which can move between the stop positions.

main body and base plate

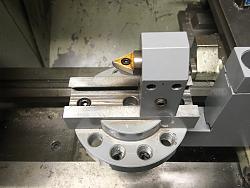

Tool post shank bolted in place

Radius attachment tool holder components. Tool holder in place

Internal radius setting jig components.

The setting gauge shaft also works as a locking pin to hold the assembly in position when setting. A grub-screw when tightened pushes the small taper pin in to the counter sink which moves the shaft down to lock in the base of the dovetail. This also enabled me to maintain the correct orientation of the shaft, so the flat face can be clamped square to the cutting tool. A slip-gauge can then be placed between both setting gauges to set correct radius from centre pivot point. Once set both the slip gauge and centre gauge are removed, leaving the clamped block in place the cutting tool is then simply moved to touch the setting gauge shaft and locked in position. Once set the setting gauge block is also removed.

Setting an internal radius using both setting gauges and slip-gauges to cut 12mm radius.

Setting an external radius using only the centre setting gauge and slip-gauge.

Operating handle and locking collar to ensure the handle can be locked in the correct orientation

Completed tool with both internal and external setting tools in place. once radius is set they are removed

Examples of radius's machined will tool

Tool held in tool-post with both internal and external setting gauges in place.

Thank you for viewing

The Home Engineer

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks