Radial Arm Saw fence

After many years of cutting a new piece of MDF for a radial arm saw fence when the old one was too “cut up”, I implemented something new. (FYI, I purchased the RAS about 1977, when I built my second storey extension).

I had purchased some aluminium extrusions that were part of a “clearance” when a local tool shop moved premises. These extrusions had been lying idle for a while. So, the next “cut up” time had arrived to fix the fence and this time, utilize the extrusions.

My design used two different length extrusions, as shown in the image below.

The new fence design used a “sandwich” of MDF-extrusion-MDF. This provided some useful benefits.

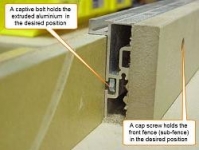

Both the front piece of MDF (I suppose it could be called a sub-fence) and the aluminium extrusion could be moved and positioned separately. The extruded fence is held in the desired position with captive bolts and the sub-fence is held in place by cap screws. The piece of MDF at the back of the extrusion was the part of the fence that remained clamped to the table (and held the whole fence in place).

As a proponent of the RAS, I was willing to utilise its various settings including swinging the RAS arm to whatever degree my job required. (I had calibrated the saw, so I was happy to change and reset the saw angles without difficulty.

As you can see in the image, the fence can be positioned to suit the angle being cut and the sub-fence could also be “closed” to allow the (MDF) sub-fence to be cut at the angle to which the arm was set, thus creating a zero clearance for the blade at that desired angle.

The extrusion was never cut. The extrusion was only repositioned conveniently close to the blade to provide strengthening support to the MDF sub-fence.

The ability to reposition the sub-fence at any time allowed the sub-fence to be closed and re-cut for zero clearance when the saw is returned to its usual 90° position.

I was never happy with the original thumbscrews - supplied with the saw - to clamp the fence in the table.

When creating the new fence I decided to implement a better clamping method. I chose to use three “over-centre” clamps. These replaced the thumbscrews in the same position along the fence.

These over centre (English spelling) made it so much more convenient to reposition the fence. My table was replaced at the same time as the new fence. I made the table 6" deeper (front to back) as I would frequently rip wide boards (yes it is safe to do this - obviously with all due care as with all power tools). The blade guard is placed just above the boards being cut. For clarity only, the guard is moved up in the image.

So now I could move the fence very easily without those pesky thumbscrews

This new clamping method was so much better.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks