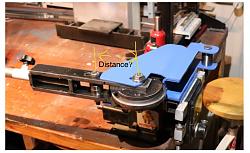

I am wondering if there is an ideal distance between the main die and the roller die for a tube bender of this type.

i currently use a Bramley manual tube bender, and notice if I put the roller cam too close, the tube will crimp when bending.

It seems there would be an ideal distance based on tube diameter and bending radius, but cannot find anything anywhere on the best placement distance for this roller. Perhaps it does not matter, as long as it is not too close?

any ideas on how to calculate optimal location for roller cam for this type of long arm tube bender would be appreciated.

cheers

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks