last week while attempting to re attach my spool gun to my mig welder I shorted a couple of wires resulting in burning one of the traces on the pcb.

upon checking for a replacement or a repair faciality the prices were all over ranging from $400.00 and up a refurbished replacement board sells for $700.00 And I didn't even want to know what Miller wanted for a new one but it turns out a brand new one from Miller would have only been an additional $75.00. However neither option is something that I was willing to dig into my piggy bank for.

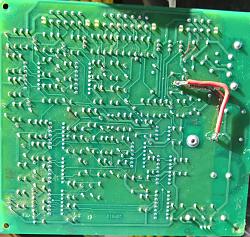

So here was the problem I could tell by looking that on the surface it appeared to be only a single trace which was burned and the board was not heavily populated in the nearby region. Now you have to understand a soldering iron in my hands is a lethal weapon mostly because I normally use a 160 or 200 watt gun or heat up a 1 lb copper iron to solder with, and for me to solder any wire smaller than 14 ga is like sending a 20 kiloton bomb to wipe out an ant hill.

Na just kidding as long as a board is not heavily populated and the connections are spaced far enough apart for me to be able to distinguish one from another I'll work on something simple like replacing a trace with a piece of insulated wire.

I wanted to use 18 or 20 ga wire for the bypass surgery but failing to have any wire that small I pulled 5 or 6 wires out of a 16 ga stranded wire then tinned up the ends and joined them to the board Had the welder going in a few minutes the piggy bank is safe from the hammer for yet another day.

By the way I do have a small 4o watt iron just for these times

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks