Here is the (quite long) story of how I built a faceplate for mounting a small 80mm precision chuck on the M33x3.5 spindle of my wood lathe.

The interest of doing that is first to have an additional chuck for this lathe, which is always useful and avoids un-chucking a workpiece and loosing its center if you need to switch to another piece before it's finished.

It's also useful to get an accurate chuck even for the wood lathe where I sometimes do also some metal work or grinding work.

I wanted to keep the benefit of the hollowed spindle and so I didn't want to use a commercial faceplate mounted on an MT2 shank.

First I use a big M33x3.5 nut. I face it on the lathe, using my slide adaptation for the tool rest.

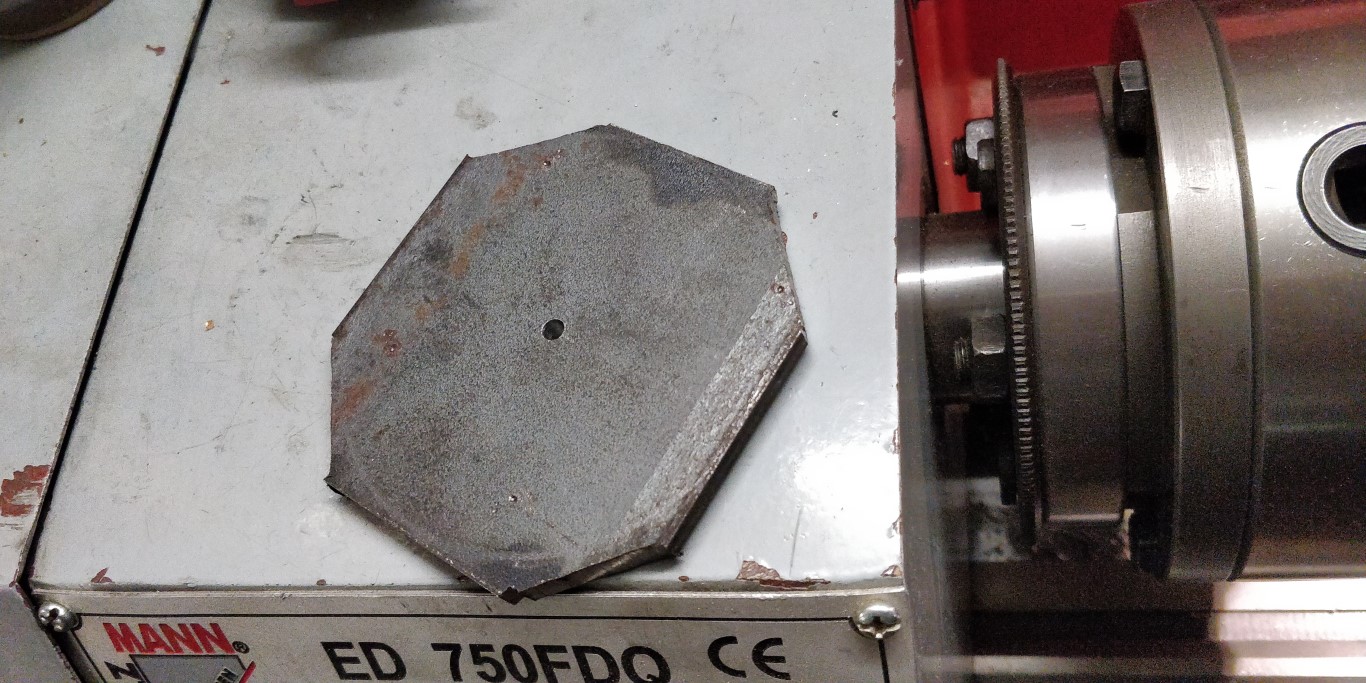

A 80mm flat stock blank.

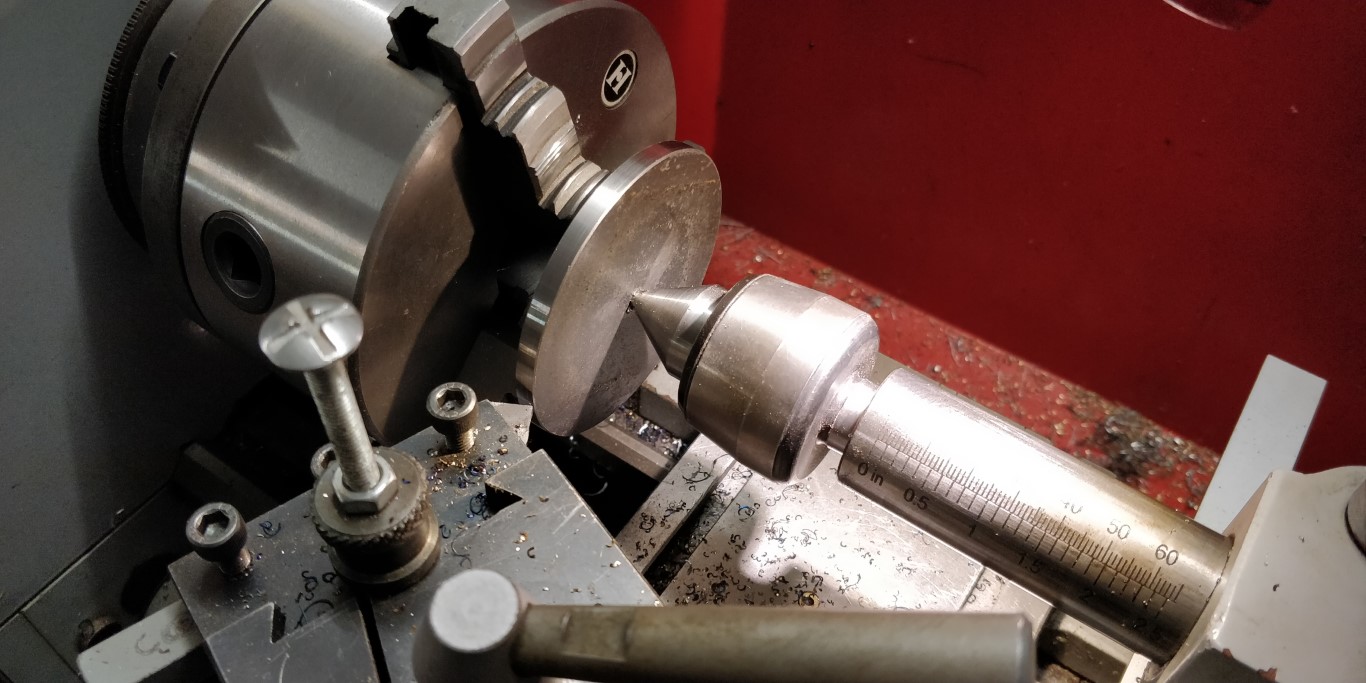

Turning it round on the metal lathe.

I mounted the nut on the spindle and applied the plate, centered with the live center, and glued with a few drops of CA glue in order to keep it centered until I weld the parts.

Welded on 3 faces only, keeping the 3 others free for getting room for the screws.

Turning down the rabbet for the back of the chuck.

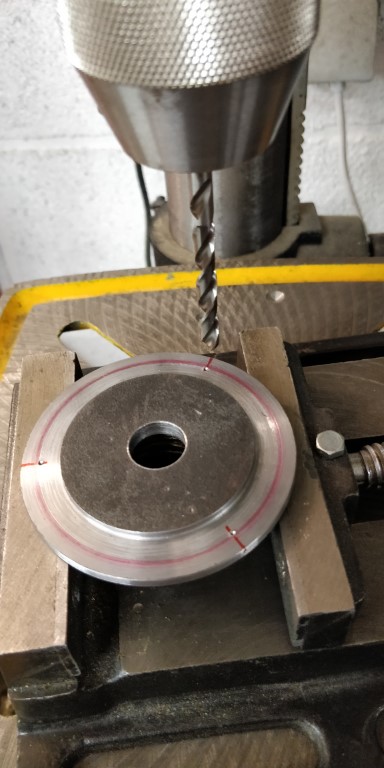

Drilling the holes.

Here I changed my mind.

I initially thought that the nut would center well enough, hitting the first shoulder after the threads on the spindle.

Unfortunately, it was not. Screwing/unscrewing the nut turned out to be non repetitive and not accurate with respect to keeping it's center.

Having a look at how the regular wood chuck is centered, I realized that it is centered on and against the next shoulder of the spindle.

So I decided to turn a ring in order to precisely fit that shoulder.

Here is where the ring goes, I still have to accurately fix it to the back of the nut.

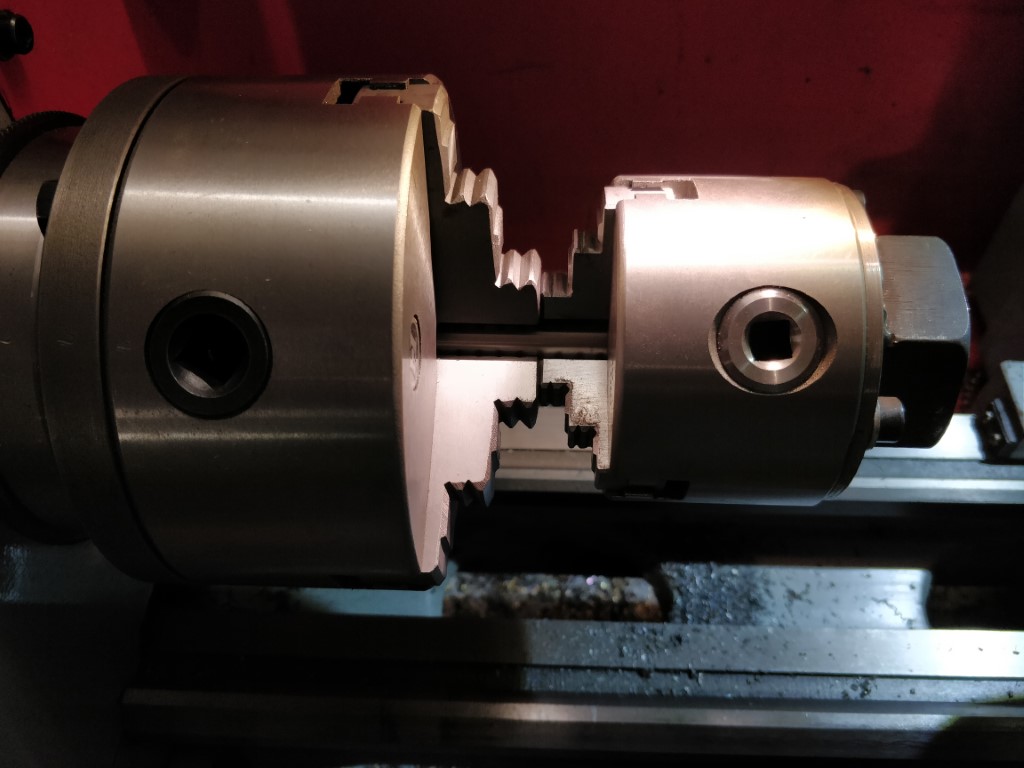

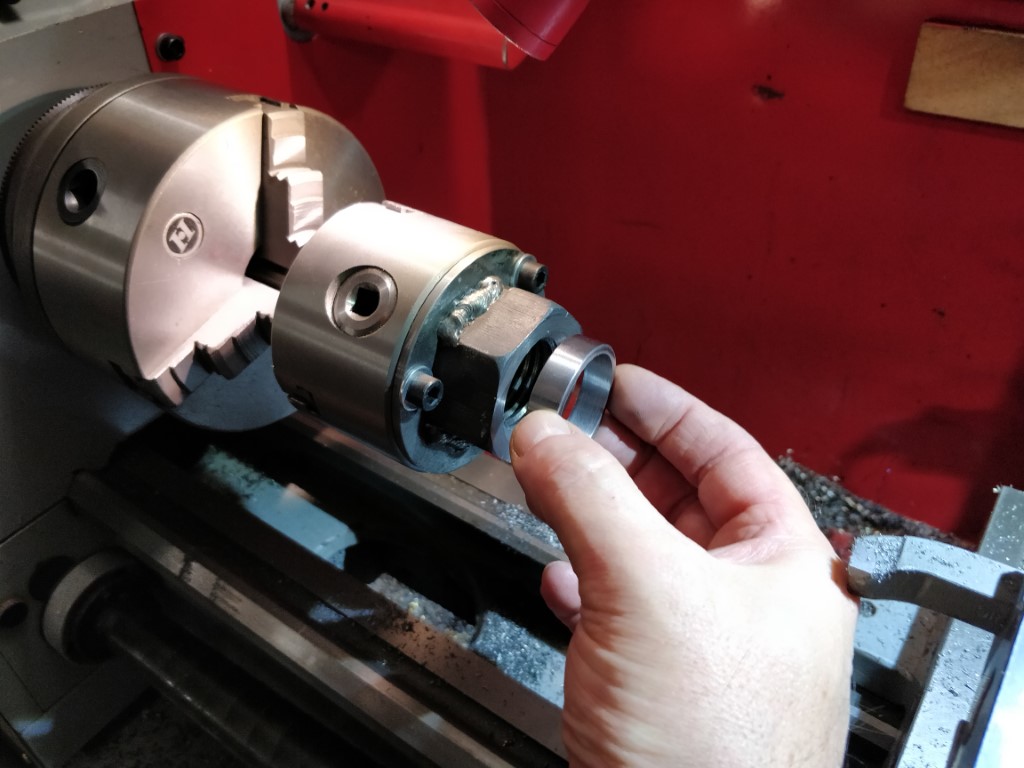

So, I installed a 12mm precisely ground HSS rod in the chuck ...

And chucked the protruding rod in the metal lathe chuck ....

... and when I saw that scene .. I started laughing out loud alone in my shop ...

This was actually what I was thinking about seeing the above picture

So, I bored an inner shoulder to just fit my ring.

I was first thinking to weld this ring but I eventually decided to simply glue it with Loctite.

There is no traction effort on that ring, and this Loctite is already very strong.

Now I have the ring installed, I had to touch up a little bit the rabbet for the chuck.

And here it it. I had to shim with a piece of paper behind a screw, and I reached an off center error within 0.02 mm at 5 cm on the rod, which fully accurate enough for my needs.

This little chuck is really nice and very accurate, and can hold small pieces, far smaller than a wood chuck would do.

I'm very happy with it and it is already at use every day I work on that lathe.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks