I made a custom light for my mill, based on a 10W power LED

These kinds of LEDs are really amazing, they provide a really bright and warm enough light, they, overall, have a low consumption, and they are really insensitive to vibrations.

The only difficulty you have to deal with is the heat they can generate and the power supply.

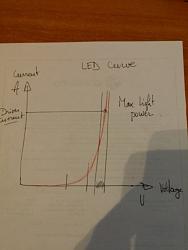

For the power supply, you must take care that LEDs are not driven by tension, but by current. You absolutely need a "LED driver", the only possibility to get the full light power from your LED. It is a common mistake to see on the Web this kind of Led driven using a voltage regulator, this will not give you the maximum light possible with your LED.

For the heat, I built a solid body aluminum case, and fixed the LED using heat grease, just like you can do with a microprocessor in a computer.

This is also the reason why in a previous post I showed how I cut a circular glass lens. If it was not the heat, I would probably have cut it out of acrylic, but here I needed glass.

Here are the separate pieces (I got the LED and driver on eBAY) :

The Led, with heat grease :

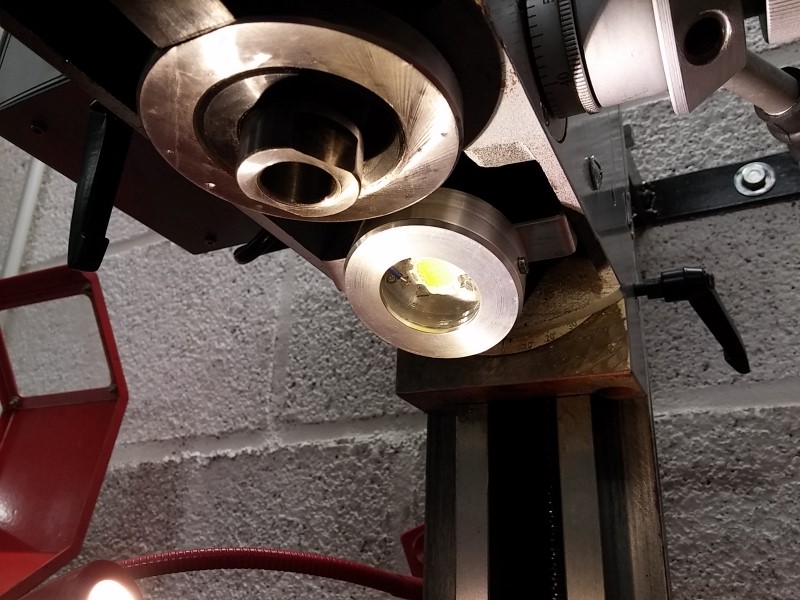

The bracket to fix it under the mill head, in the cavity. Several holes to be able to set up the depth and orientation.

Here it is in place :

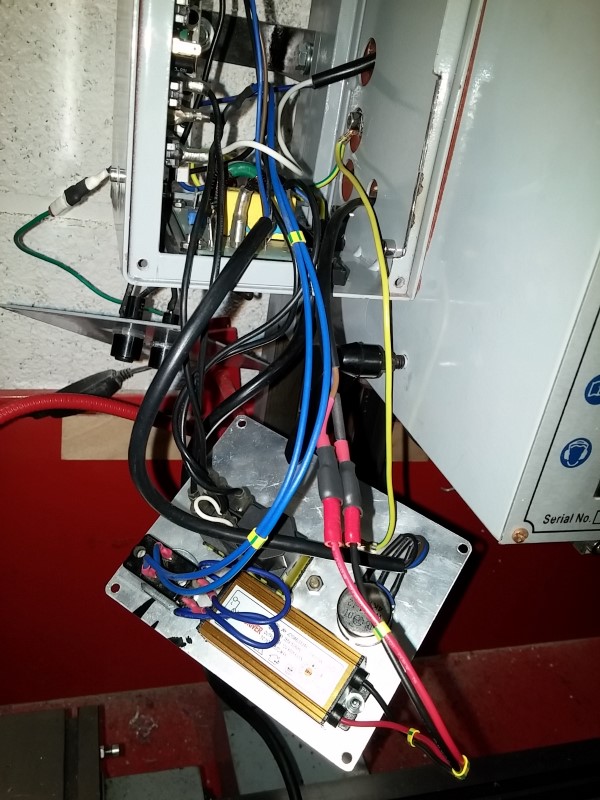

I installed the driver and a switch in the command box of the mill.

The new switch, top right.

And here we go, plenty of light !

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks