Hi all,

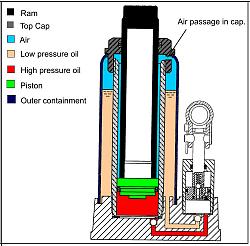

Just wondering if it would be possible to convert a typical automotive type bottle jack to pull rather than push?

I've never seen it done before. I know you can buy the pull back type rams with the external hand pump but am after something with the pump integrated with the cylinder.

Anyone seen this done before?

Thanks

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks