This might be the most helpful; yet simplest, item I have made for my workshop.

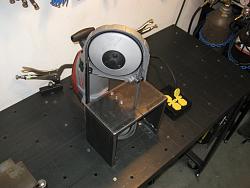

It is a ‘Vertical Tabletop Stand’ for a portable ‘Deep Cut’ Variable Speed Band Saw that I purchased from the reconditioned area in the Milwaukee Tool Store.

The Milwaukee 6230N 'Deep Cut' Portable Band Saw Portable Band is Plugged into an Extension Cord On/Off Switch.

The short story is I wanted a portable band saw I could use outside the shop, but needed a way to justify buying it since I knew it would not get used very often outside the workshop. Then I noticed a vertical tabletop stand online and decided to make a stand of my own using leftover metal from the scrap bin.

( My favorite hobby – Scrap Metal Tool Design! *GRIN* )

I had some 6″ wide by 1/2″ thick flat-bar steel leftover from when I made my welding table and I cut it into 3 parts and welded it together. Then I looked around my workshop and found some 1 1/4″ angle-iron in the scrap bin. Cut the angle-metal to length, drilled some holes in it, and welded the angle to the Flat-bar portion. ( Not the most complicated item ever designed *Smile* )

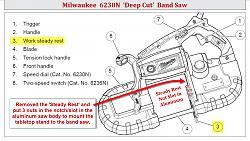

Next, I removed the Cut-Guide ( Work-Steady Attachment ) from the Portable Band Saw to measure the hole dimensions for drilling of the new tabletop stand.

Once the holes were drilled and counter-sunk ( allowing the mounting screws to match up with the nuts located inside the slot in the saw’s aluminum body ) … I then used the porta-band-saw to cut the ‘blade slot’ in the stand top.

Then it was just a matter of screwing the band saw to the new vertical tabletop stand, and then using a set of all-thread rods to connect it to the welding table.

It would be an understatement to say I use this Vertical Stand more than I expected. It is quick to setup, easy to use, and if I tip the stand and saw on its side I can change the blades with the stand still attached to the Porta-Band-Saw.

The band saw trigger is held down with an elastic Velcro strip … its variable speed dial is still adjustable … and the unit is turned On/Off with a plug-in switch.

If needed to cut some metal on those occasional projects outside the workshop… It takes about 30 seconds to unscrew the portable band saw from the stand.

The same day the Vertical Porta-Band-Saw Stand unit was finished, I used it to cut some stainless steel for a friend using a 24TPI (teeth per inch) blade and it cut very accurately through the flat-bar like butter … Justifying the project. :-)

As you can see in the photo above – since the vice can be bolted down anywhere on my welding table – I used a bent piece of scrap sheet-metal clamped in the vice as a support to hold the long Stainless Steel flat-bar steady and level as I cut it into different shapes with the ‘Deep Cut’ portable band saw.

That’s it… a pretty Simple Stupid design… but it works!!

–CHEERS…

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks