A new member was asking how to drill square holes so I thought I would share a process that I have used successfully in the past

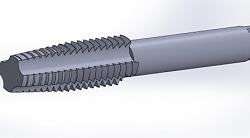

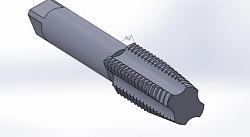

for instance to make a 5/16" square hole in soft material or even in mild steel as long as it is not too thick I have taken a 7/16" NC starting tap and ground it square. the teeth will broach out the material to make a square hole. Care must be taken when doing it like this because the 60° cut angle is wrong for this application

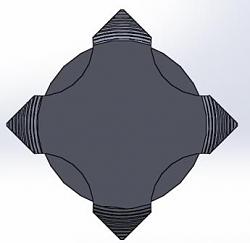

press the modified tap through the holes

here is a drawing of how the tap would look

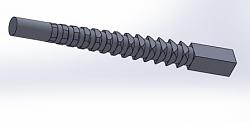

Ideally you would use a 5/16 sq piece of tool steel ground to the shape of a broach

like this

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks