Not a new idea as many old lathes had such an attachment driven from overhead drive but with small modern motors a more compact solution is possible.

I should state from the beginning that this is not the ideal design but based solely on what I had in the scrap bin and old stock.

My old SB lathe has plain cast iron bearings which do not like high speeds, my usual working speed is around 600 rpm, this is a problem for small drills. The solution was to make a high speed drilling spindle to plug in the tailstock with minimal setup, in fact by rotating the stock and the drill a truer result can be had.

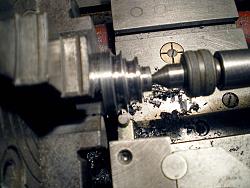

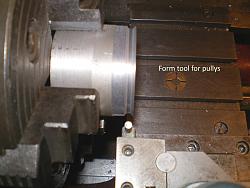

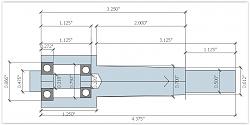

I had an old Archer keyless precision 0 to .25 inch chuck which I rarely use which seemed ideal, the integral hardened 1 morse taper was turned down using a CBN tool and cut off to fit two sealed bearings which I had and pulleys were made. An 18v DC motor from an old cordless drill as the power source, and a drive belt from a large O ring I found which I remove when not in use to avoid over stretching, this gives a top speed of 12000 rpm +600 if I also run the lathe.

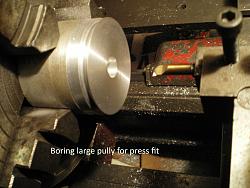

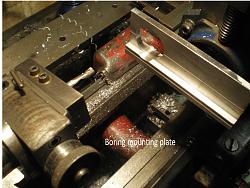

That just left a No 2 taper housing to make from a piece of weight lifting bar I had and a mounting bracket from a piece of alloy extrusion. I can power this from my PWM 18v battery power box and And in the absence of a sensitive feed I will for now peck drill by sliding the whole tailstock by hand pressure for tiny drills. The shortened taper is because my topslide travel is 2 inches and the parallel portion enables self ejection. It can also be used as a live tailstock chuck for turning parts too small for a centre i.e. fuel needles.

The reason for making this is a need to make some new jets for a 100 year old AMAC carburettor.

Update

The old drill motor was a bit lacking so it is now powered by the ubiquitous 775 which is ok for drills up to 5 mm.

Next project is a sensitive lever feed but not for quite a while as I am moving house and workshop.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks