I am planning on an upcoming build that will require several pieces of 1 1/2" pipe to be notched so I decided to make a holder for my lathe so I could use it to notch my pipes.

Ordinarily I would just torch out the saddles then dress them up with a grinder, or I would use a chop saw set at 30° or 25° depending on the radius of the saddle I wanted. I have made saddle cuts on my band saw using the same method.

When I had my Turret lathe I used shell mills and the pipe holders I had made for it but that stuff is long gone now.Time to build a simple device to notch the pipes for the task at hand

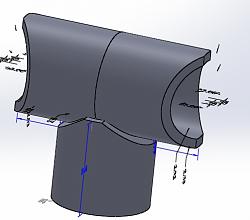

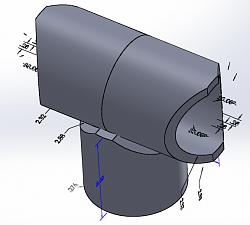

I started with a 8" long piece of 2" pipe then drilled 3 holes in it for the clamping bolts then welded nuts to the holes I had drilled in it and a mounting plate to bolt to my compound unit.

Here you see me checking the center height against my compound unit before I welded anything together

Checking the depth of cut before making the notch

to make the notches since I no longer have the shell mills I decided to try using a hole saw the saddles needed to fit a 2" pipe

A 2 3/8 hole saw is a perfect fit to make a saddle for the 2" pipe header

This works fairly well albeit a lot slower than any other method

to make sure that 2 pipes are the same length it is a simple matter of holding one against the hole saw and positioning the header pipe against the opposite ends of both pipes then just tighten the set bolts and it is ready to make the 4th saddle. Using a header pipe also helps to insure the saddles are parallel to each other

Eventually the pipes will be welded together to make the control arms for a tracing torch. Which I need to build so I can make several duplicate parts that will be used to make a wide variety of items one of which hopefully will be a 1/4" by 96" folding break

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks