yeah right get inside to work those timber will keep it standing.

Ralph

Sincerely,

Toolmaker51

...we'll learn more by wandering than searching...

PJs (Dec 12, 2018)

Admittedly, that demolition-from-inside is probably at or near maximum craziness. I don't think we'll be able to beat it. However, maybe we can top it:

New plans added on 01/17/2025: Click here for 2,706 plans for homemade tools.

PJs (Dec 12, 2018), rlm98253 (Dec 12, 2018), Seedtick (Dec 12, 2018), that_other_guy (May 24, 2019)

‘‘Always do right. This will gratify some people and astonish the rest.’’

Mark Twain

While I don't have any pictures of it in operation in the early 90's I made what I called the arms of destruction for a customer to use in demolishing a reinforced concrete chimney that was inside of a 41 story hotel. The top 30 feet that stuck above the building was brick. That was the easy part just erect a scaffold around it and use electric hammers to break the bricks loose let them fall to the bottom and hauls them away with a skid steer. But from roof level on down it was concrete with a 2 ring re bar reinforcement spaced every 10 inches with vertical bars on 6 inch spacing's.

Prior to his getting the contract 2 other companies had tried the demo of it. they had taken a few months just to remove the brick work down to the roof.

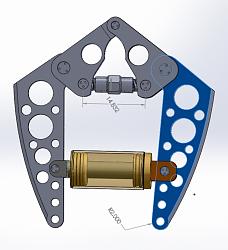

When he got the contract His initial plan was to just cut the concrete into small blocks and remove it that way. but after only 2 days he decided there had to be another way. So he and I sat down and came up with a design for breaking the concrete from inside. this is what we came up with

I made the arms out of 2 inch thick t1 steel . I made the turnbuckle out of 3" hydraulic cylinder rod the nut for the turnbuckle was just a piece of 5" hex I found at the scrap yard the pins were made out of cylinder rods as well.

we powered it with a 16 Hp Honda with a 4 to 1 2 s stage pump. We had to carry it to the roof in pieces since the arms alone weighed 150 Lbs. used a chain hoist to lower it into the chimney. then once adjusted it was simply a matter of open and close then rotate and do it again the foot thick concrete broke up in chunks we used a torch to cut the re bars as the concrete was broken away. in 18 days we had the chimney removed. At times so much concrete was falling out the slanded steel ramp we had made at the bottom that 2 skid steers couldn't keep up with the removal.

Never try to tell me it can't be done

When I have to paint I use KBS products

IAMSatisfied (Dec 12, 2018), PJs (Dec 12, 2018), rlm98253 (Dec 12, 2018), that_other_guy (May 24, 2019), Toolmaker51 (Dec 12, 2018)

Nice design, Very cool Frank. Curious how you fed and released the cylinder...must have been a double acting cylinder and switch/valving? And keeping the lines (400ft) & fittings from harm must have been a bit of a challenge.

Last edited by PJs; Dec 12, 2018 at 11:42 AM.

‘‘Always do right. This will gratify some people and astonish the rest.’’

Mark Twain

There are currently 1 users browsing this thread. (0 members and 1 guests)

Bookmarks