In the dark days before computers, if you wanted to rescale a drawing you had to do it by hand. For small drawings or working from a prototype, a set of proportional dividers were useful. The first photo shows a commercial pair of these neat tools.

Basically they are a double-ended set of dividers with a pivot point that is movable. By setting the pivot in the right location you can set the ratio between the openings of the two ends of the dividers. The second photo shows detail of the pivot mechanism and the ratio scales engraved on the arms of the tool.

This tool is still made and sold. You can buy one from MicroMark for a staggering $95.00 ...

https://www.micromark.com/Proportional-Divider

(If you want to buy one, search for a better price; MicroMark is notoriously overpriced.)

They're a great tool but using one to rescale an entire drawing can be very tedious. The tool for that job is the pantograph.

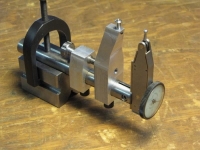

One of the reasons we have shops is so we can build the toys we couldn't afford when we were kids. As soon as I got some tools capable of working metal I set out to build a pantograph as a good way to teach me how to use those tools. The tool that resulted looks like this...

The arms are 21" long and made of 3/4 x 1/8" aluminum to keep the weight low. A variety of pivot holes allows the unit to be set to ratios between 1.25:1 to 10:1, roughly the same ratios the proportional dividers can manage.

This picture...

shows the working end of the tool. On the left is the hold-down which is clamped to the work table while the tool is in use. Attached in the middle to two of the arms is the tracer point with which one traces lines in the source drawing. On the right arm is fixed the pencil lead holder that marks the scaled drawing. If you build one, a better choice for the marker is a felt-tip pen since the pencil can glide and not leave a clear mark on occasion. A weight on the right arm can overcome that but the felt-tip is a better solution. The tracer point and pencil lead holders were salvaged from an old set of drafting instruments.

The junction of the two central arms at the other end of the tool has a gliding foot that rides on the worktable...

This foot is needed to keep the arms from twisting and binding when the tool is in use.

All in all, it was a good learning project for a young metalworker and, once done, was actually used in anger on a few occasions to rescale drawings. Of course, today it's as outmoded as a drafting machine but I still hang on to it just to confuse my heirs when they encounter it while throwing out all the rest of the stuff in the shop.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks