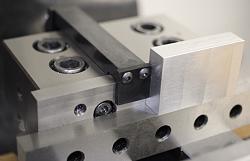

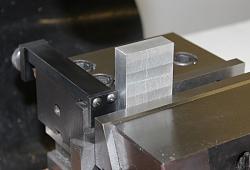

One advantage of the Kurt mill vises & their lookalikes is that they they have rectangular jaws. They lend themselves to jaw replacement, sacrificial jaws and those clamp-on work stops. I'm a big fan of stops. They help a lot with accuracy as the part can go in & out as often as you like & preserve the same position. Unfortunately my (Bison 5") mill vise has prismatic jaws. I shouldn't complain because its super accurate. But you cant use the typical rectangular clamp on stop due to the taper on the back face & also there is very little lip. I have a stop that comes in from the side but it takes a little longer to set up. When you have little parts around the middle of the jaw, the clamp-on kind of stops are easier.

So I came up with this arrangement. Its basically a steel bar with a bolt on front lip stop. It saved me milling away a bunch of material from solid & gives me flexibility to attach different thicknesses or custom shapes of stop plates if I choose. I had to relieve a notch in the top bar so it would clear the jaw protrusion. The rest lies flat on the top of the vise block. My vise also has big cap screw heads protruding proud on the block but I decided to not relieve for those or there would be little left of the bar to lay flat on. So my range is just a bit limited between the socket heads but it will be fine.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks