Warning: You're approaching wall-of-text area! No vids or ads!

Disclaimer: To all of you truly inventive minds, I unfortunately have to say that:

this thread is NOT about hooking up a naval outboard motor to a lathe -

but merely an additional PMDC worm drive to a lathe's spindle.

-Sorry for crushing everybody's false hopes - but then, it's someone's sad mission to do that too...

-Lack of torque in the lo rev range of lathes is a common complaint,

and having a 7 x 14" chinese assembled kit lathe I'm lazy enough

NOT to build an add-on back gear assembly or some jack-shaft kludgery in the tight motor compartment.

Also, not particularly needing to crack the Hi-Lo POM plastic intermediate gear in the headstock either...

I'm not at all putting these methods down - to each his own,

I'm just all for the simple, cheap and fast git-it-done, and hence I figured:

While soon fixing a threaded spindle spider to the headstock (for stock stick-out support),

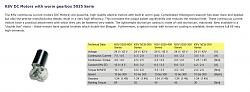

I thought: -Why not "just add" one of those < 500 W, <75 Nm torque, <200 rpm worm gear PMDC drives lying around?

Mounting that worm drive rigidly and non-intrusively to the left end of the headstock,

working thru some dog clutch directly at the spider,

I could get all the no-hostage torque for threading I'd ever need,

instead of farting around with my manual handle

(as I've already found that my winding introduces some to and fro warp to the bed for each turn).

A side benefit would be that the "pure torque" will then only be applied axially to the spindle,

and the resulting counterforces would be taken up by the headstock housing directly and entirely,

NOT by some gear, chain or belt that could bend and offset the spindle axis relative to the bed.

A 1 kW, 50 VDC max PWM cheap motor control will provide all the juice necessary

(fed by an E-bike LiPo power pack & charger I got (for FREE!) from a work buddy that had his E-bike stolen).

I haven't actually seen any project like this tried anywhere on the Interweb,

so now I share this idea, hoping the collective consciousness of HMT will pitch in!

Ideas, suggestions for, and problems in this approach most welcome!

Cheers and TIA, Johan

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

) are great for high power at pretty high revs,

) are great for high power at pretty high revs,

Bookmarks