How old? 1896! Yes as in Eighteen Ninety Six.

Planning floor layout details.

As real work in building gets going, one issue is maximizing usable area. Rent, lease, or buy; cost is considered primarily in square feet. When building, the height becomes another factor. But within considerations mentioned, the available CUBIC feet are kind of free. I moved here for that exact reason. What I bought equaled 18 months rent in Southern California. Replacing the entire roof works out 46 months total. While eventual goals aren't disclosed, they'll unfold as it goes along. What is in my favor, while 3-4 places are similar within 100 mile radius, they're promoted in very old school ways.

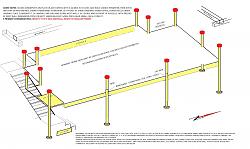

So, in July the punch presses moved in, where a mezzanine is next. That added 560 sq ft will clear shop floor with machine tools already in place. This will be self built. A big impasse of interior height 15' 8" is thickness of combined deck material. Past few days I fleshed ideas that have been in mind awhile. The pic expands with notations. Seems 'Lift Pocket' only feature that won't make the cut.

Once the floor grating thickness is known [lbs. per square foot], the supporting structure materials will be factored. Frank S likes doubled purlin "I-beams" as economical, easy to handle joist material. They'll center 28.5.

More vertical savings would be how to use pallet rack beams; being indented with a step. They don't seem available in sufficient [desired] length. Is moving posts inboard under the splice practical?

The stair and landings work with a short 'dead' wall space, without blocking adjacent drive through door. The open corner fits around head of large press, it's 10' 6" tall.

Certainly, will consider and rework accordingly with every suggestion from entire HMT community.

Just tested diagram, it opens quite large, text readable by scrolling a bit.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks