Every time I oil my equipment I always think that a special oiling apparatus for those spring loaded ball oilers would be great, I have made several different sizes of tips to fit the spouts on oil cans that worked ok but some of those spring loaded ball oilers can be a little difficult to get oil into, I needed more pressure to force the oil into the spring loaded ball oiler, kind of like a hypodermic needle.

Years ago I worked at Machine Shop and we had an oiler that was kind of like a hypodermic needle, it was about an inch and a quarter in diameter with a total length of about ten inches and had a tapered point that fit the hole in the spring loaded ball oiler, I never took it apart and examined the internal components but all you had to do insert the tapered point into the hole of the spring loaded ball oiler and give it a push, sometimes if you had the oiler a little crooked when you were pushing it would leak a little but it would still inject oil into the ball oiler, I have never seen an oiler like this since I left there, although I havenít looked for one either but Iím sure somewhere someone makes these things.

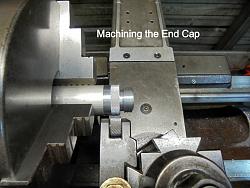

This is my version of that oiler; itís very simple in design and consists of only six machined parts with four O-Rings, I made the nozzle to fit the smallest ball oiler I had which also worked out for the larger ones as well, like I mentioned itís just a big hypodermic needle that holds 3 ounces of oil.

Below you will find some photos of the machining process and the completed oiler being used.

As always Thanks For Looking

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks