Hey guys

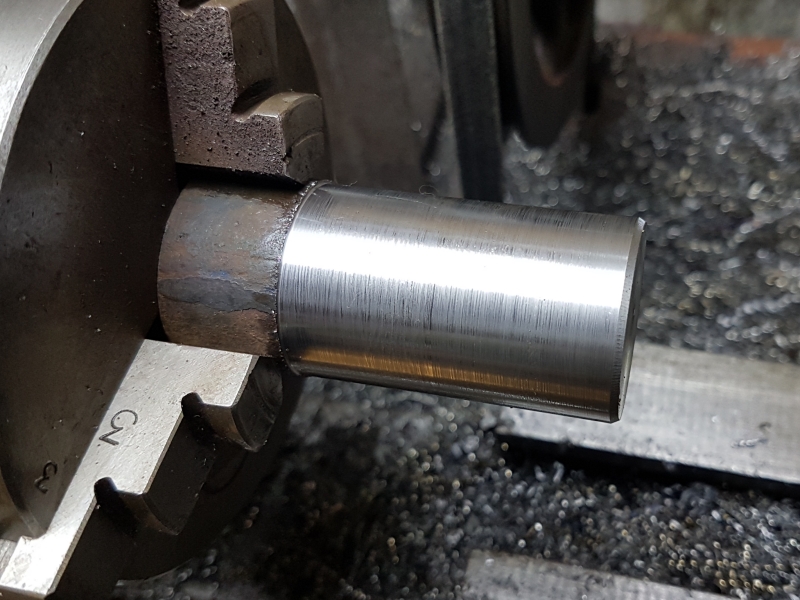

After dinner, I got onto making the peg. The first thing I did was to face the part and skim off the scale and rust. I just used my three jaw for that as it was nice and quick:

Once that was done, I swapped to my four jaw, turned the part round, dialled it in and did the same the other end, in this case though, it already had a shallow but somewhat off centre hole drilled in it, unfortunately though, I got quite carried away with precedings and forgot to take pics of a few stages, sorry.

Anyhoo, despite the off centre hole, I took a 6mm bit and drilled it to just over an inch deep and while I wasn't too keen on the way the bit flexed while I did so, I wasn't concerned about it being off centre as there's a simple way to bring a hole back on centre without having to bore it all the way down.

The trick is to take a small boring bar and used it to true up the hole just enough to clear the offset while making sure not to overshoot the tap drill diameter.

The bore need only go to depth of about 10mm or so into the hole and once done, it's then possible to swap back to drilling again as the portion of the hole that has just been bored acts as a drill guide which prevents the larger bits from wandering as it cuts the rest of the hole to depth:

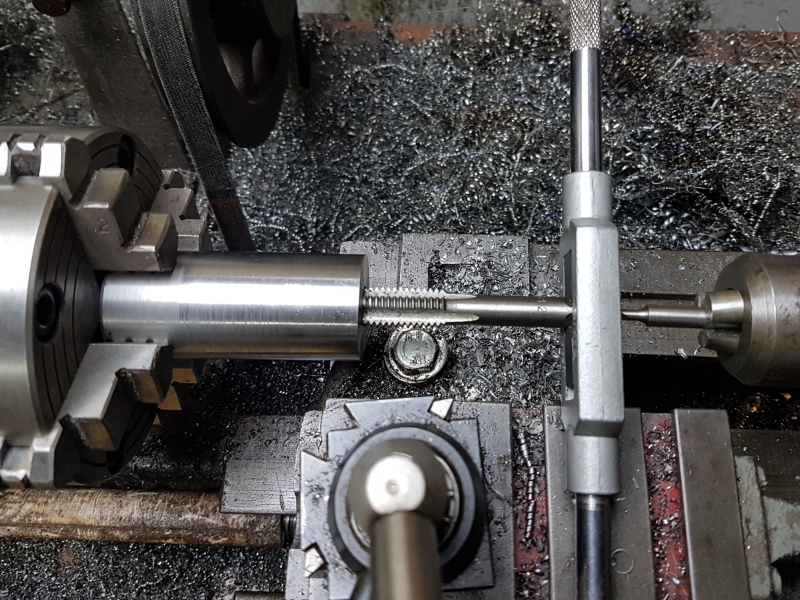

I then put the lathe in back gear and used it to get the tap started:

It did quite a good job and managed quite a few turns and then finished it by hand when it got deep enough:

With that done, the only thing left to do was test fit it:

Well that's it for today's progress, I'll catch you all again soon

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks