Hi folks

I nanaged to get a half day this week so spent some time after I finished to make use of works mag drill.

Of course, I should have realised things wouldn't be so straightforward and the first little spanner I came across was that the quill on works mag drill is totally opposite to mine and terminates in a stub, not a bore.

There was an arbor for anular cutters that came with it but it's 6" long, so it doesn't leave much daylight underneath and total travel is only 50mm.

Given the limitations, I did the receiver platform holes first but will have to start over as ironically, the holes for the pins (which are critical) wandered off centre and the bolt holes ended up being dead nuts, which is entirely the opposite scenario I was going for.

The second spanner showed up when trying to put the holes in the hight blocks. Mounting it directly to the frame didn't work as there wasn't enough travel to cut the hole all the way through. I couldn't mount it to the same surface that the frame was sitting on either as the cutter wouldn't lift high enough to clear the blocks, so I threw the towel in, put stuff away and did some hard thinking all day at work.

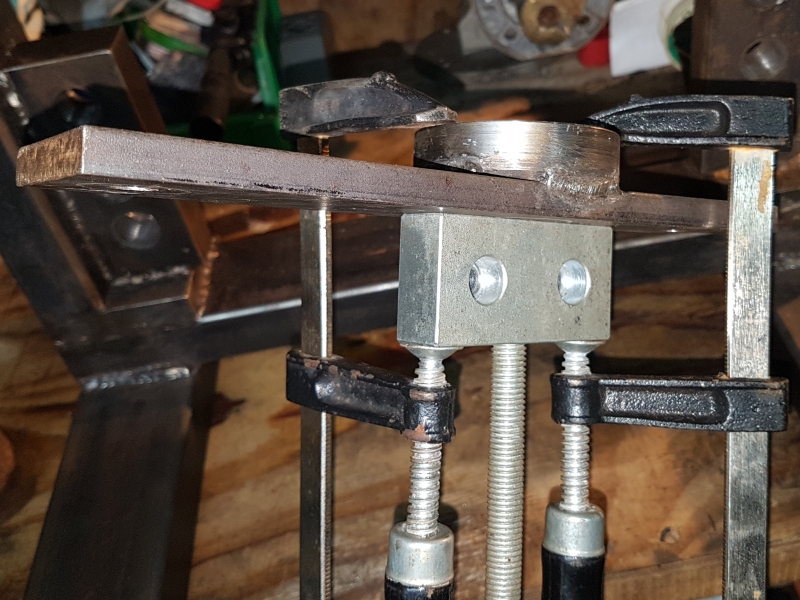

Well, the only thing I could think of at the time was to cut a length of 4"x1/2" plate and tack weld it between the blocks so the mag drill had a surface it could attach to at the correct hight but that has a set of problems all it's own that took a great deal of figuring out how to do and involved a lot of side projects.

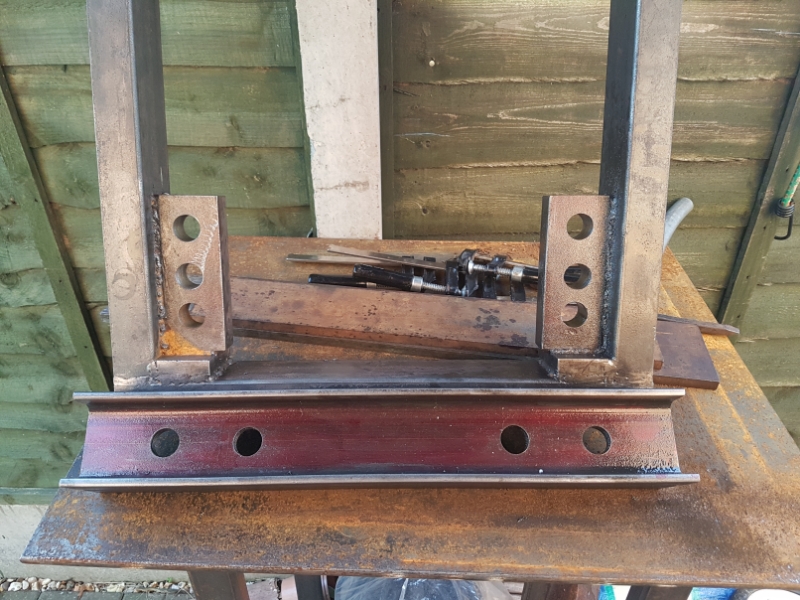

It wasn't until I was sitting down in my workshop contemplating the problem, cup of tea in hand, that a much less complicated solution presented itself when my eyes reston on a couple lengths of shock absorber shaft my friend had dropped off a few days ago. Unlike most shocks I'm used to seeing, these are thick walled hollow tubing and the first thing I noticed is that the bore looked to be just right size for the shank of my anular cutter:

After tidying up the roughly cut end with my grinder, I tested my theory and found it to be a perfect fit with just .025mm of wiggle room so I decided it would be simpler to just make the shock into a shorter adaptor for the mag drill.

After grinding some flats for drilling at 90° to each other at both ends, I took the piece with me to work and I used their drill press to make some holes for locking grub screws.

It was here I found out just how hard this stuff is to work with and if the bit stopped cutting enough to rub, it was game over, even for brand new factory ground bits.

I hadn't realised how blunt the bit had got after the first hole, so that resulted in the first divet, attempting to cut the first divet with new bit only succeeded in bunting it.

I then reground the first wrecked bit as that one was mine and proceeded to cut the second hole, which almost went all the way through, so I reground it again and was able to finish it but not without a small struggle.

Figuring in the fresh grind, I started the first hole on the other side, but even that small amount of cutting meant the bit was blunt on the outer flanks of the cutting edge and once again it was game over after just starting it, thus producing the second divet.

Given it's behaviour so far I fretted a little over tapping this stuff but it turned out to be much more amicable toward that job and happily there were no dramas. Despite only having one locking screw, the anular cutter is very tightly held and definitely not going anywhere and with at least one hole made at each end, it wasn't a totally lost cause, so I went and got the mag drill from R&D.

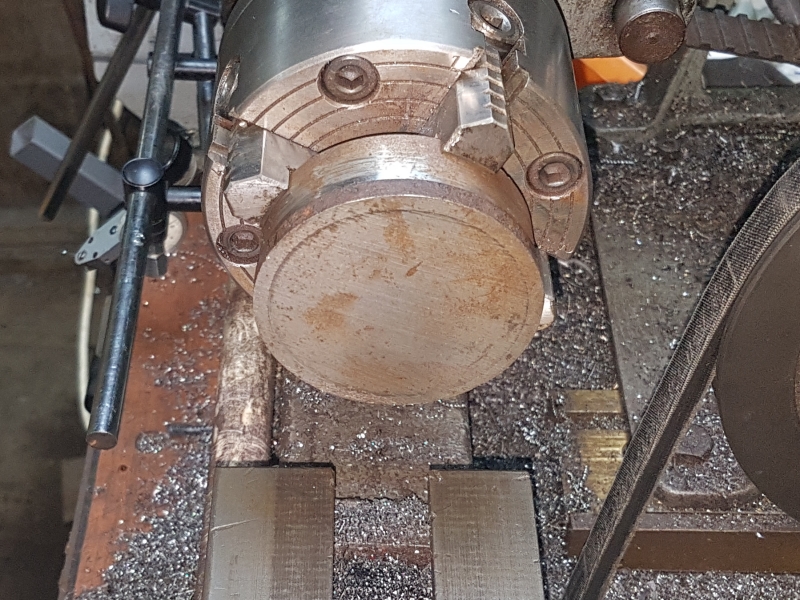

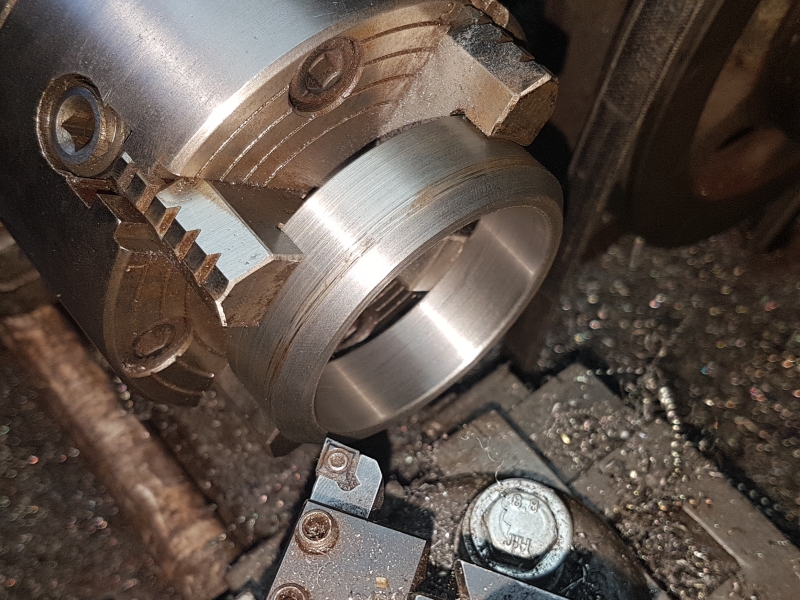

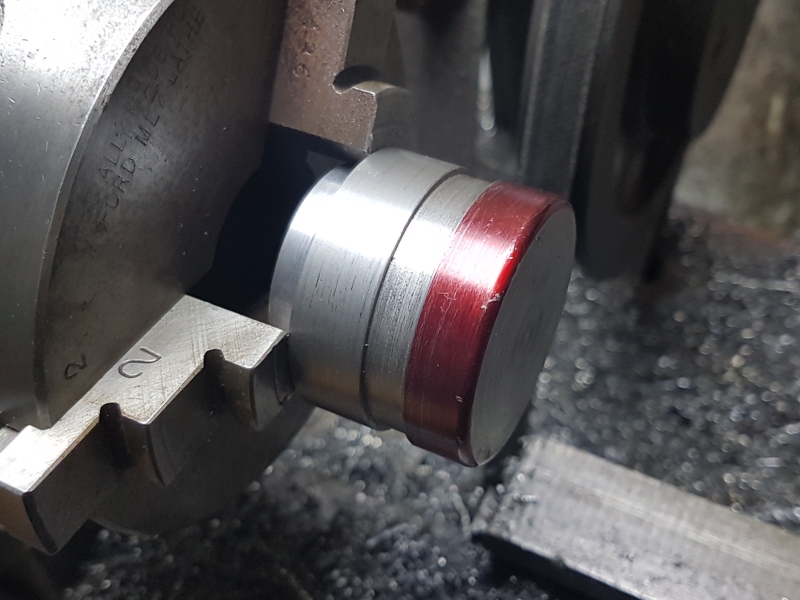

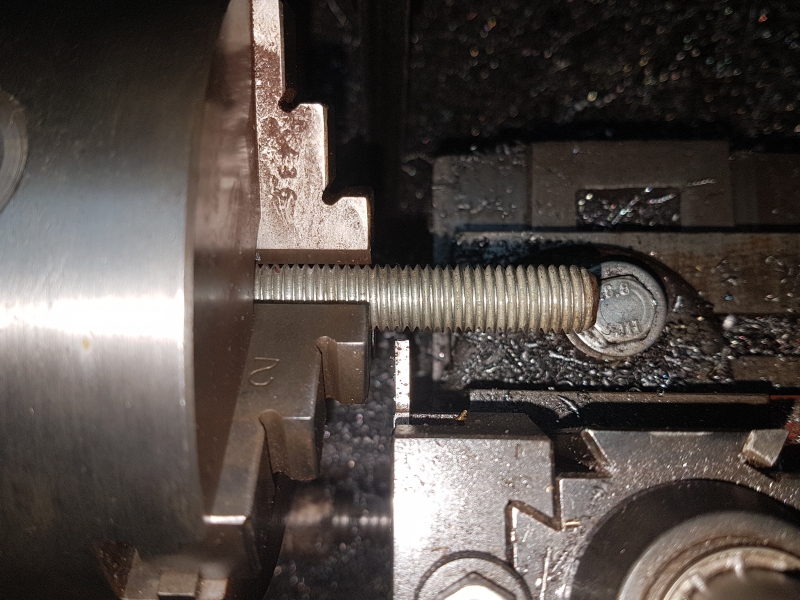

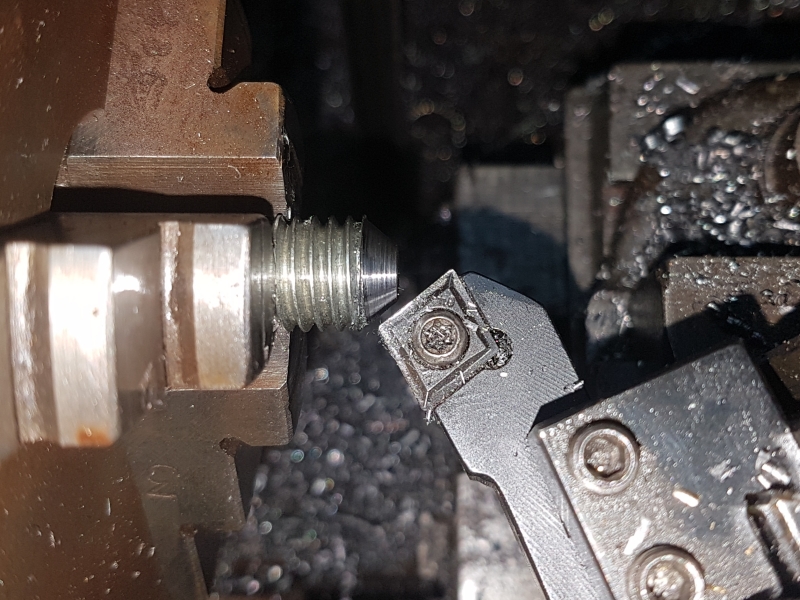

It was at this point I found spanner number three as the quill stub was too large for the bore by 1mm. After getting home I chucked it up in my four jaw and managed to get it to within .00025" of centre and bored it at low speed using carbide tooling:

It fits the mag drill stub with just the tiniest amount of interference, which is exactly what I was aiming for, my biggest worry was overshooting and ending up with play, so I was very happy with the results.

I haven't had a chance to try it out yet, I'll have to wait till Monday for that but hopefully I'll be able to finish the holes so I can finally progress with the build.

Until then, have a good weekend and I'll catch you all round

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks