Yes Canobi, the present set-up [part length-diameter-depth of chuck jaws] exceed border of parting off that cylinder. MAYBE right up at the jaws, nowhere else.

I'd hesitate less with a live center in the open end; scoring a line for the saw. Just set dial zero a couple hundred short of penetrating the hole, but perfect parting cutter alignment and dependable flow of coolant would be fairly critical. None of those avoid stick-out; biggest problem of all.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

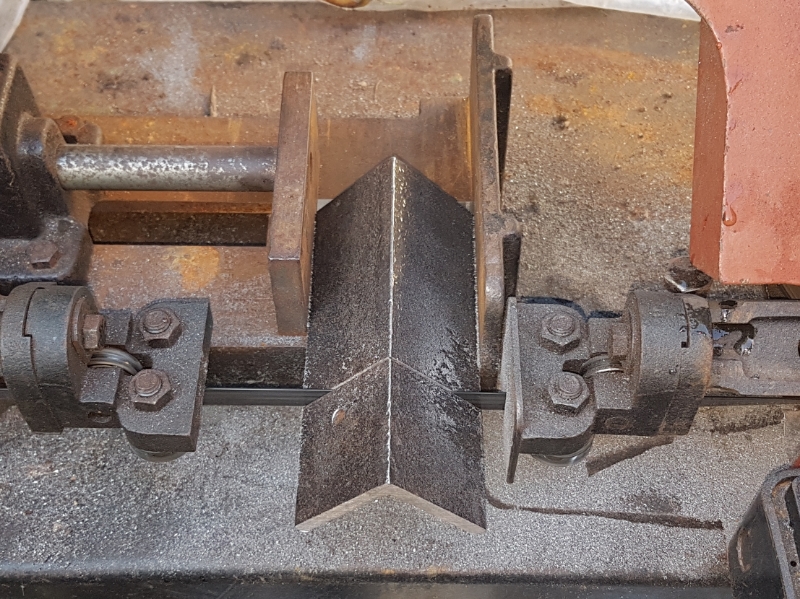

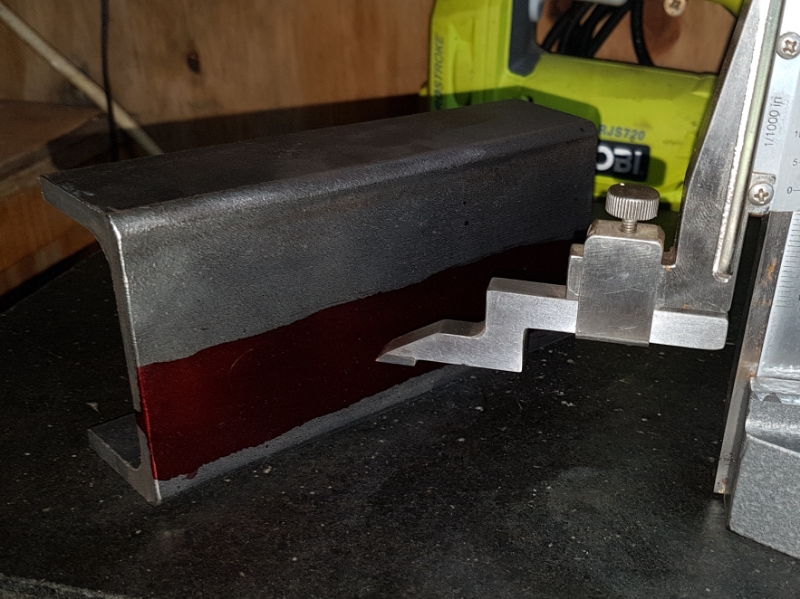

I made a start on the spacers today and the first one is nearly done, though it's been tough for my little old lathe working such a large piece. I'm now facing the spacer to length as I didn't like how much blade stick out there would have to be using my parting tool, it's slow going but safer: More soon...

I made a start on the spacers today and the first one is nearly done, though it's been tough for my little old lathe working such a large piece. I'm now facing the spacer to length as I didn't like how much blade stick out there would have to be using my parting tool, it's slow going but safer: More soon...

Reply With Quote

Reply With Quote

Bookmarks