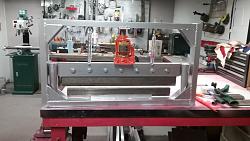

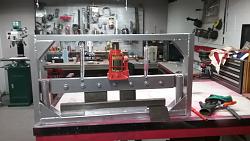

Hello all, I found this site by accident and was completely blown away. I do sheet metal fabrication for a living, but find it very boring. Making practical cool stuff at home is awesome. Here is a picture of my latest project, bottle jack press brake. I made it so top and bottom dies could be changed out.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks