Originally Posted by

Geoff Keyes

USS_Cuttlefish,

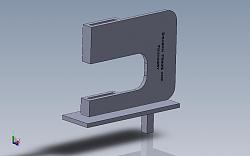

That design will work, but.... You need to make it more robust than you think. .5" or .750 for the frame, and you may want to add gussets to keep it from twisting. I would use 4140 or 4340 for the tooling, full hard it will be about 52 Rc, which is plenty hard for forging hot steel.

You may also want to make some kind of hold down, tooling like this bounces when stuck. A spring clamp, or a wedge underneath the heel of the anvil will be a big help. Don't wedge down into the hardy hole, you can break the heel off that way.. Another way to go would be a stand alone tool that sits on it's own block or post. I'm thinking a piece of pipe in a 5 gallon bucket, filled with concrete. The tool would have a shank that went into the post with a wedge or a bolt through it.

Geoff

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks