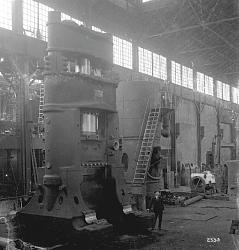

well my guy is on his way to pick up my new hobby lathe at least that is what I told him it was. he knows he is going to pick up nearly a full step deck trailer load of machines for me but I wish I could be there to see the look on his face when he sees this little lathe

My wife asked me what I was going to use it for and I said I don't know maybe sharpen pencils with it.

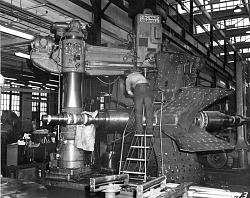

It is factory raised to be able to turn the full 36" over the carriage

total length is between 21 to 23 feet. So I'm guessing maybe 10 or 12 between centers

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks