Originally Posted by

KustomsbyKent

Hey guys,

I'm looking for suggestions on boring out the center of some plastic wheels to a larger bore.

Background:

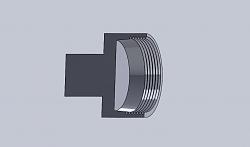

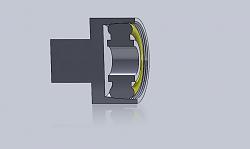

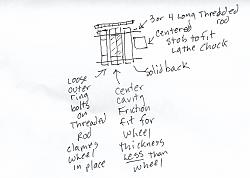

2 types of wheels, a 8" outer diameter, and a 5" outer diameter. The wheels are a Polyurethane core with a soft perimeter. They come with a 1.188" bore for an unsealed roller bearing.

I am boring them out on both sides to accept a 1.375" OD sealed ball bearing, 2 per wheel.

I have successfully chucked these into a 4 jaw chuck using dial indicator to zero the runout, and machine out one side, then flip it over and do the other side. I typically machined each bore to about 1.368 to 1.372 so the bearing fit fairly tight. I did the first 24 wheels this way... but it's slow. Because of the soft outer layer of the wheel, tightening the 4-jaw chuck down to zero runout is time consuming. The actual machining is fairly quick.

Looking to optimize, I ordered a set of adjustable reamers, and just got those. I tried them the other night on a single wheel, and it works, but is slower. I had to use 2 of the adjustable reamers. Starting with the smaller reamer, I locked it in the vice, adjusted it until it was just starting to cut, and then turned the wheel by hand down onto the reamer. Adjusting it larger, and doing again & again & again, until that reamer was maxed out. Then I switched out to the larger reamer, and crept up on the final size.

It didn't require any specialized equipment, resulted in a nice finish, and the bearing fit well, but it took even longer than machining them.

Future looking, I will need to do more of these wheels in batches of 24, in a mix of 8" and 5" wheels.

What are your suggestions for doing this quicker/easier? You can't take off too much material at one time, as the material is a bit spongy so it flexes as you machine. Small cuts seems to work the best. Holding these is a problem with the soft outer portion. They are also not perfectly concentric from center to outer diameter, but it's not critical since this is all a low speed final application.... 7 mph.

Thanks

Kent

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks