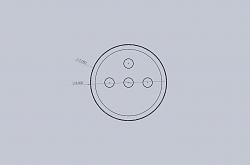

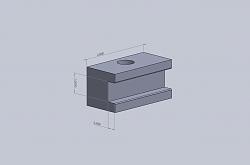

I am building a die to bend 1" square, I have a 8" O.D. x 2" Round die that I have machined a 1.05 inch wide by .5 inch deep groove. *I was going to make the back plate 4" long and machine the same groove into it. *But the truth is I am just guessing, I want to know if anyone could tell me if you machine in exactly 1/2 of the thickness of the material you are going to bend or something I dont know about. * Thanks to anyone that can send me in the right direction. * *I also wanted to know if there was a formula to how long the back plate has to be in relation to the material you are bending and the O.D. of the bending die. *I attached some pictures so you can understand my rambling.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks