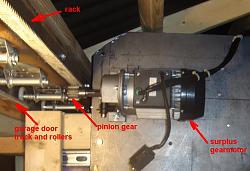

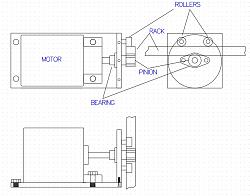

A few years back I built my own "roll-off" roof mechanism for a backyard observatory. The roof is free to roll on an off. The mechanism is very simple. There is a long rack (linear gear) permanently attached to the base of the roof on one side. A reversible motor drives a pinion which engages the rack to move it either to the open or closed position. The roof is guided by a set of garage door rails and wheels. Recently, the pinion has been slipping out of the rack when trying to open the roof. If I pull down on the roof near where the pinion engages it does help and eventually the roof will open. However, I getting to old to do this because it takes a lot of force to keep the pinion and rack engaged. I have been trying to come up with a way to maintain the engagement between the driven pinion and rack, maybe a couple of idler pinions mounted below the driven gear and pushing it up against the pinion. The following photos should give you an idea of the setup.

Many thanks, Frank

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

Bookmarks