Heyyyya there everyone,

As a Millwright my background is mostly in metal working~metal machining~ and mechanical. But I do have enough experience with wood working to get in and out of trouble most of the time.

A couple months ago I stumbled across a brand new never used HF sandblast cabinet with 10~20lb bags of grit for 20$!(No not stolen~lol... wife was divorcing and was selling everything of his off cheap) Since the cabinet did not come with a vac/recovery system I learned really quick why you Do Need one in about 30sec of using the first time do to my whole shop was covered in grit dust! And Yesss I am still finding grit dust after about 2months later. Since I am the the kinda person that has a hard time buying something that I can take pride in making not only Bigger~Badder~Better but make last, I started researching on how to make a recovery dust separater for going on 2 months in my spare time and boy have I have learned a lot and also have been confused several times!

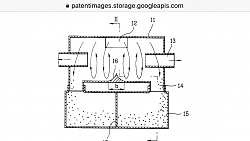

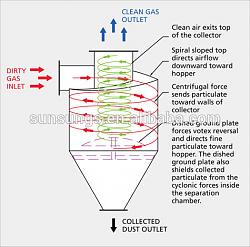

There is many ways to do this right and wrong. Everything from cyclonic~multiple cyclone~baffle system~ to axial cyclone systems like Dysonís vacuum cleaners. After searching page after pages~forum after forums this is the first forum I registered with after reading all of the posts here!

This forum has taught me a lot and has answered a lot of questions thanks to You and all of your comments and posts!!!! This forum not only actually answers your questions and helps you understand the ďwhat~why~whereĒ but dosnt treat you like your stupid!

So here is my question/questions and I feel real confident that Iím in good hands here!.....

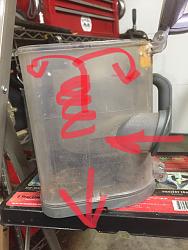

How I got the idea for this was one night a while ago during some research on the inter~web I needed to a break to let my thoughts settle and grabbed the vacuum cleaner to vacuum up my shop floor and work benches ( yes I said vacuum cleaner not shop vac! Itís our old house one and works great 👍 for cleaning shop floors~better than broom and dust pan!!! Faster too) it does not have a cyclone or multiple cyclones in it but it is bag less..it is a cyclonic style. Iíll post pic of it... but anyway as I was doing this the 💡 came on and then confusion/dyslexia set in at same time....lol

I would like to build a bag less all~in~one system to reclaim~separate~and filter out the fine dust blast media or sand using a shop vac... I am not sure if I want to make an R2D2 pancake system or not yet. I have 2 different shop vaca. One is a standard Crapsman wet/dry 3.25 hp 8 gal one that blows exhaust out the sides below motor. The other one is a 16 gallon Hoover 2 tank wet/dry with a wet tank and dry separator switch that has 216 airwatts of suction (which I have found out that is a true suction reading vs hp~but I canít find what it converts to as hp) and has a blower accessory port but also exhausts like other on.

I learned from from a different sight that a cyclone system takes more to pull air through than Thienís baffle system.

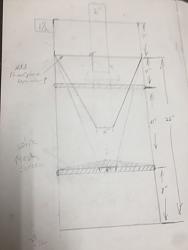

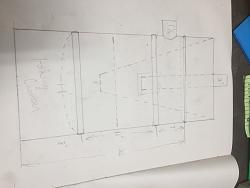

So that being said... what I want to build (and since Iím trying to reclaim sand everything needs to be metal) since space is a problem Iíd like to try and build a cyclone inside either one of my 30 or 35 gal metal oil drum. Or I can build a Jp baffle top hat system or combine them both. But hereís the one of the problems I also need help with... i need to pull media/sand from blast cabinet and separate the media/sand from dust/garbage and have the dust in a separate container or compartment. Preferably on top of drum. I have drawings of what my thoughts are that I will post.

Has anyone tried putting a cyclone inside drum instead of on top like a vacuum cleaner?

Ty

Shawn

Ps...

Iím adding some pics of a horizontal system that I stumbled across and looking for thoughts on that too...

Shoot I canít upload pics from phone!!! This makes things harder! Grrrr help!!!

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

idea... I will make up a sketch of this. What if I put the exhaust pipe at the edge of top which is also the edge of cyclone with a 90* elbow facing the same way or opposite way of inlet like Jp’s Baffle? But do I make another baffle plate under elbow??? Putting and baffle under elbow like Jp’s design would make it to where most of actual dust stays in drum... uggg anyway Ill have to figure this out and experiment as I go.. This would make 2 cyclones in one. One outside and one inside utilizing the inside walls of the cycle to help extract more dust and separate more media?...! Or I could reverse the inlet and exhaust. The 1 1/2” inlet could be in the top and 2” exhaust out the side Or 1 1/2” intake on top and 2” exhaust on the side. GREAT Grrrrrr my brain is hurting now!!! Uggg more confusion!

idea... I will make up a sketch of this. What if I put the exhaust pipe at the edge of top which is also the edge of cyclone with a 90* elbow facing the same way or opposite way of inlet like Jp’s Baffle? But do I make another baffle plate under elbow??? Putting and baffle under elbow like Jp’s design would make it to where most of actual dust stays in drum... uggg anyway Ill have to figure this out and experiment as I go.. This would make 2 cyclones in one. One outside and one inside utilizing the inside walls of the cycle to help extract more dust and separate more media?...! Or I could reverse the inlet and exhaust. The 1 1/2” inlet could be in the top and 2” exhaust out the side Or 1 1/2” intake on top and 2” exhaust on the side. GREAT Grrrrrr my brain is hurting now!!! Uggg more confusion!

Bookmarks