Hello zipp,

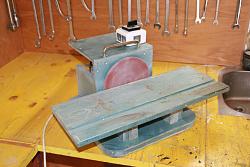

the pottery wheel is a very simple one. It uses a old washing machine motor and pulley. Those motors have 2 speeds, 315 rpm and 2800 rpm. Only the slow winding is used, and you want your wheel spinning at around 60-70 rpm. For making more delicate object like tall slender vases, you will want a wheel with adjustable speed, 3 - 120 rpm for example. But for a beginner, the simple on off type is enough. I have attached a picture, under the motor is an additional fan, because the motor at 315 rpm does not have enough cooling to run for more than 5 mins (good enough for the washing machine, but not for the pottery wheel

)

Make sure the switch is waterproof, and no water can get on the electrical parts...

here are a few of my homebuilts :

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

)

)

Bookmarks